What is Cp and Cpk?

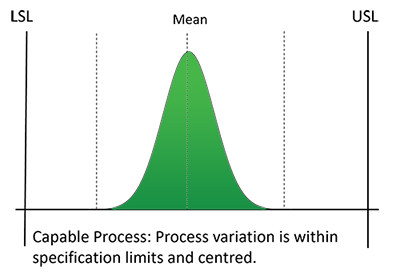

Understanding Cp and Cpk in the context of Process Capability Analysis is necessary for assessing the capability of manufacturing and production processes. These indices provide insights into how well a process can produce outputs that meet predefined specifications.

What is the Process Capability Index (Cp)?

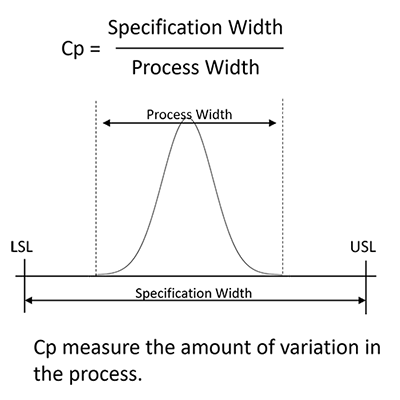

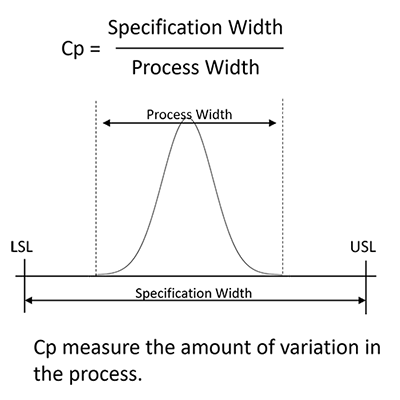

Cp, or the Process Capability Index, is a fundamental measure in process capability analysis. It evaluates a process’s ability to produce outputs within the specified limits under the assumption that the process is statistically stable, or in control.

Cp is used to assess the potential of a process to meet specification limits without considering the actual position of the mean of the process.

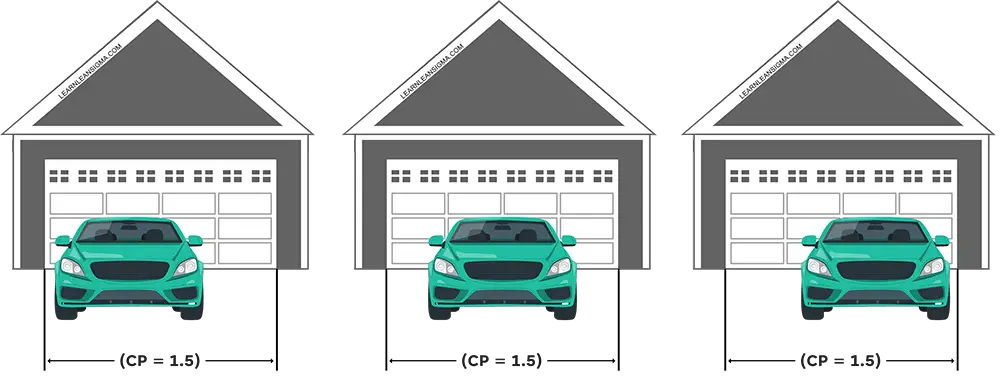

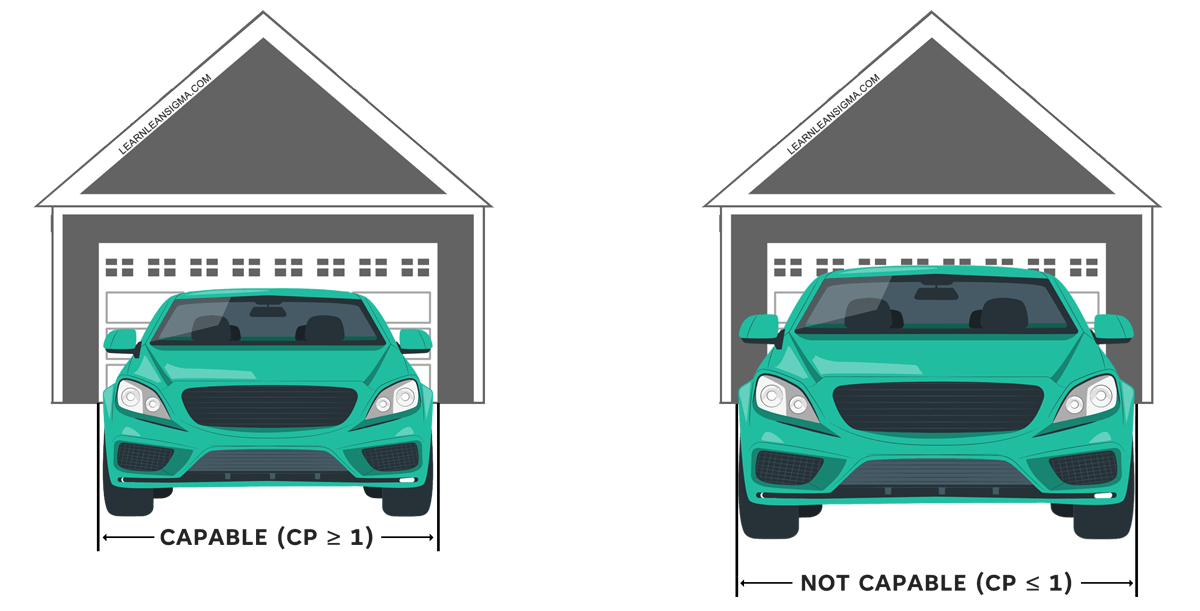

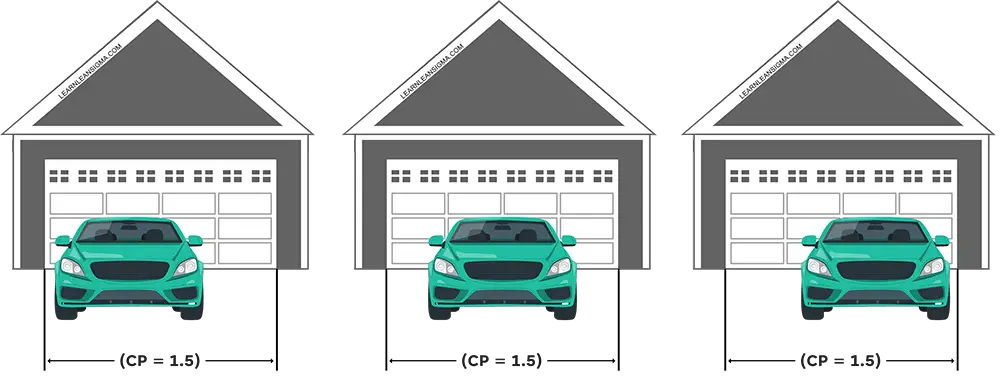

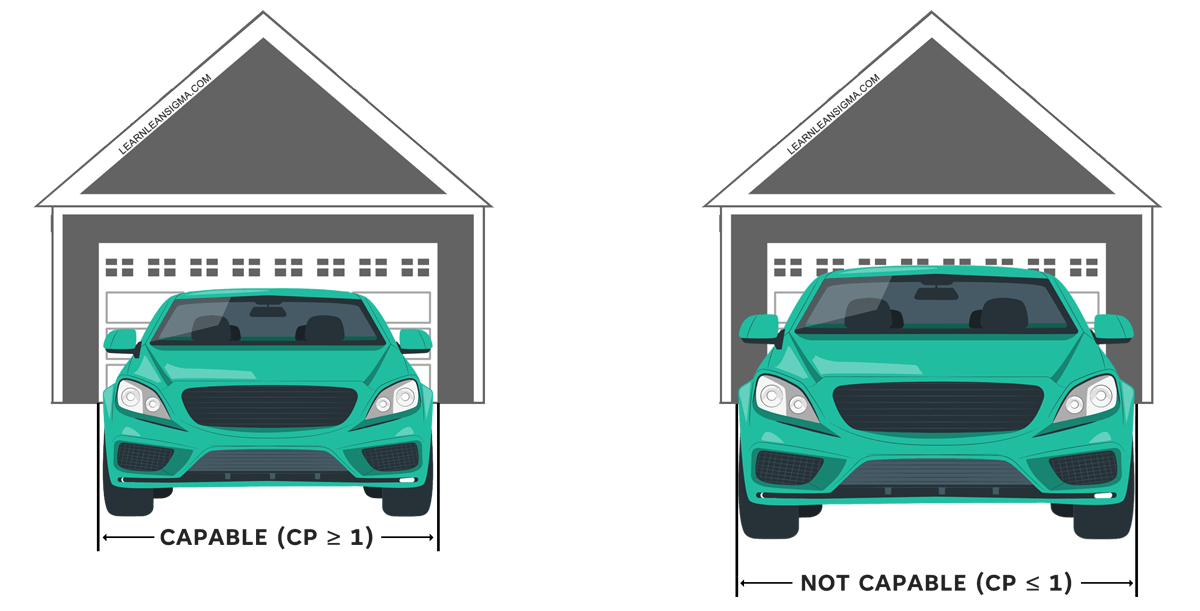

For this illustrative purposes let’s consider the width of a car is the amount of variation in the process, and the garage walls are the process limits UCL and LCL. If the car can fit into the garage without hitting the wall, we would say it is capable and would have a Cp score of at least 1. If the width of the car is greater than the width of the garage we would say the car is not capable and would have a Cp score of less than 1.

For this, if the car hits or scapes the sides of the garage entrance we would class that as a defect. But when the car is capable of fitting into the garage as it is narrower than the width of the entrance AND the car is centred the car will fit and therefore not be a defect.

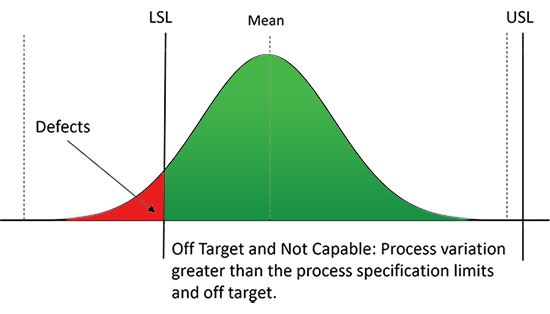

However, with Cp alone we do NOT consider if the car was in the center as it goes into the garage therefore the process would not be capable with a Cp of 1 and an off-center process. Cpk is a measure of process capability as well as how well-centred the process is. We will cover the Cpk measurement in more detail below.

First you need to understand the calculation of Cp then you will be able to understand the Cpk calculation and understand if your process is capable and centered in the process.

What is the Process Capability Index (Cp) Calculation?

In this formula:

In this formula:

- USL (Upper Specification Limit): The maximum acceptable value for the process output.

- LSL (Lower Specification Limit): The minimum acceptable

value for the process output. - σ (Standard Deviation): A measure of the process’s variability.

If you are not sure how to calculate standard deviation you can look at our guide on Standard deviation or use our standard deviation calculator to help with this step.

Example Calculation Process Capability (Cp) Calculation

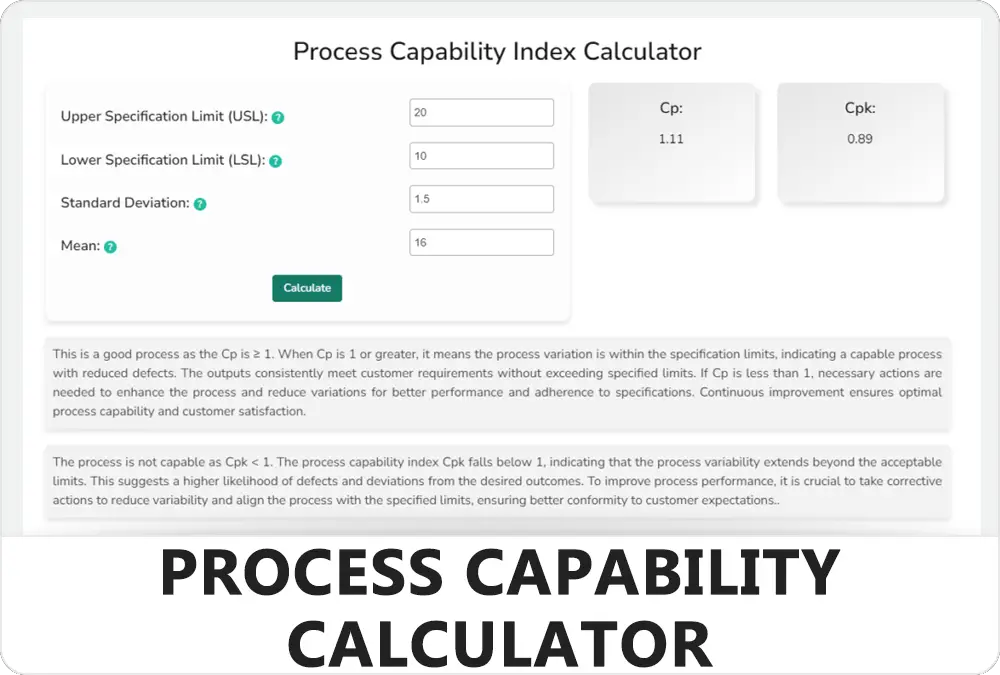

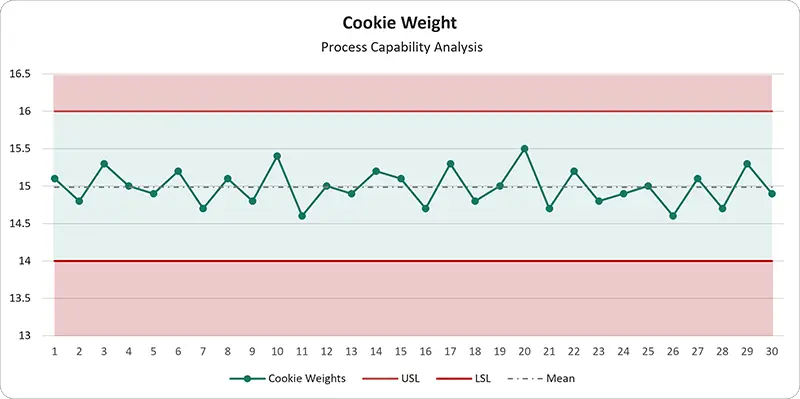

Continuing with the cookie example to calculate Cp of cookie weights let’s revisit the scenario and the data. Remember, our focus is on the weight of the cookies, with the Upper Specification Limit (USL) set at 16 grams and the Lower Specification Limit (LSL) at 14 grams.

- USL (Upper Specification Limit): 16 grams

- LSL (Lower Specification Limit): 14 grams

- Standard Deviation (σ): 0.24 grams

So using the formula from above we need to do the following:

- USL – LSL: 16-14 = 2

- Standard Deviation X 6: 0.24 x 6 = 1.44

- 2 Divided by 1.44 = 1.39

- Cp = 1.39

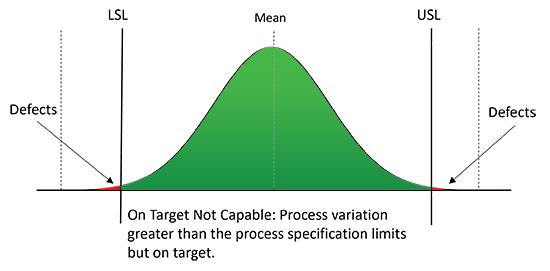

The Cp of 1.39 suggests that the process is capable of producing cookies within the specification limits (USL and LSL). However, this is only true if we know the process is centred within the limits, and the amount of variation suggested is capable but if the mean cookie weight is 15.5 some of the cookies could be over the specification weight and therefore classed as defects. So to understand how well centered the process is we need to understand and calculate the Cpk, which is the next step.

What is the Process Capability Index (Cpk)?

Cpk, or the Corrected Process Capability Index, improves the Cp measure by incorporating the mean’s position relative to the specification limits. This index is crucial for understanding both the variability and the centrality of the process.

Cpk is used to assess a process’s capability to produce outputs within specification limits while considering the actual position of the process mean. It’s a more realistic measure of a process’s capability.

Consider the following scenario: We calculated a process capability index (Cp) of 1.5, indicating that the process can comfortably produce within the specified limits, much like cars being able to fit in a garage. However, even with a Cp of 1.5, not all cars are centered in the garage; similarly, our process might not be centered between the upper and lower specification limits (USL and LSL).

It’s important to note that a process can have a Cp of 1 or higher and still not be perfectly centered within the specification limits. To address this, we should calculate the process capability index (Cpk), which considers both the spread and the centering of the process relative to the target. This helps us understand if the process is truly capable when factoring in the desired target.

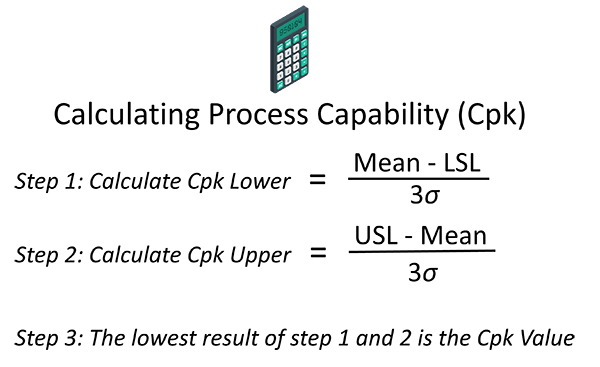

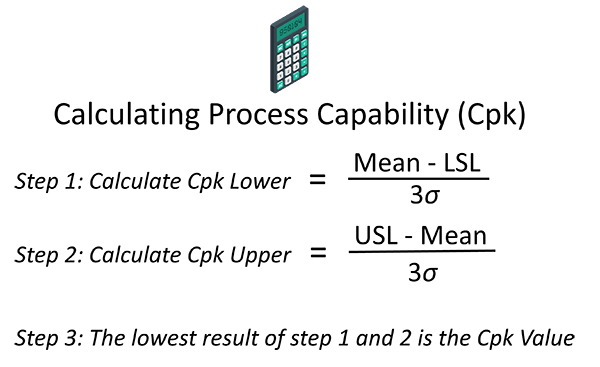

What is the Process Capability Index (Cpk) Calculation?

In the Cpk formula, we consider the same elements as in Cp (USL, LSL, and standard deviation), but we also include the process mean (Xˉ):

- USL (Upper Specification Limit): The maximum acceptable value for the process output.

- LSL (Lower Specification Limit): The minimum acceptable value for the process output.

- σ (Standard Deviation): A measure of the process’s variability.

- Xˉ (Process Mean): The average value of the process output.

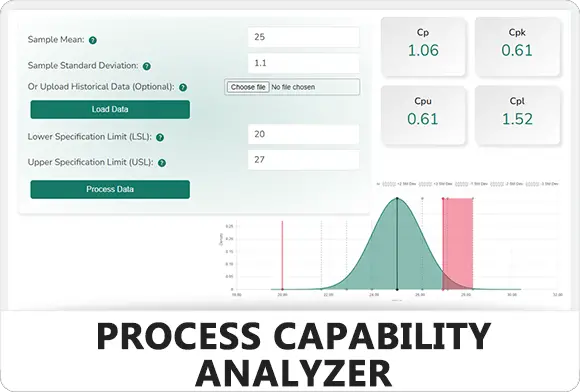

To calculate the Cpk we need to calculate the distance of process edge to upper spec limit (Cpu) and the distance of the process edge to the lower spec limit (Cpl) and then take the lowest value of those two results.

Example Calculation: Process Capability (Cpk) Calculation

Let’s continue with the cookie example for calculating Cpk of cookie weights. We already know the USL, LSL, and standard deviation. Now, suppose the average weight of the cookies (Xˉ) is 15.2 grams. Using the formula, we need to calculate:

- Cpk Lower calculation (Step1 – Calculate top and bottom) = (15.2 – 14) / (3 x 0.24)

- Cpk Lower Calculation (step 2 – Divide top by bottom) =1.2 / 0.72 = 1.67

Cpk (Lower) = 1.67

- Cpk Upper calculations (step 1 – calculate top and bottom) = (16 – 15.2) / (3 x 0.24)

- Cpk Upper Calculation (Step 2 – Divide top by bottom) = 0.8 / 0.72 = 1.11

Cpk (Upper) = 1.11

So, the Cpk for this process is the lower of the two values, which is 1.11. This value indicates that while the process is capable, the centering of the cookie weights is not optimal, as reflected by the Cpk being lower than the Cp. It suggests that there is room for improvement in centering the process closer to the target mean.

In this formula:

In this formula: