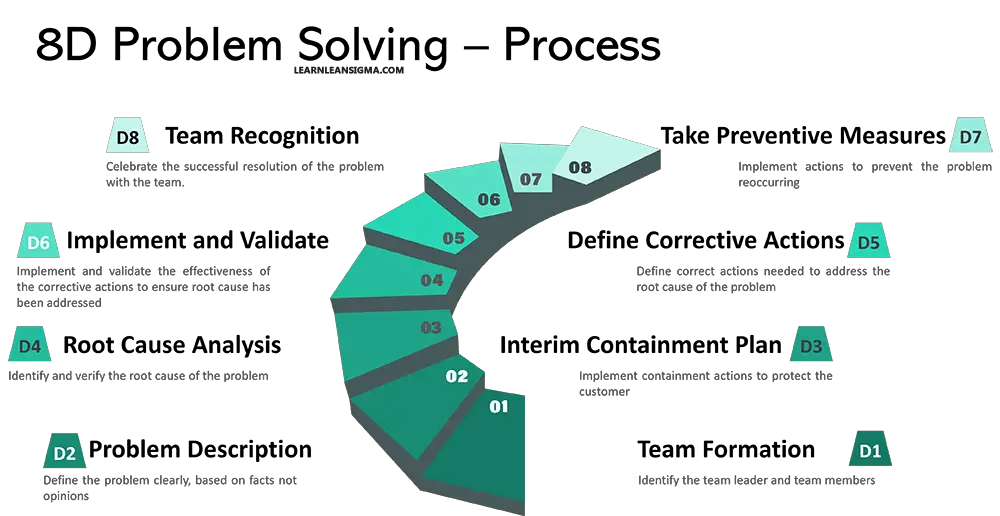

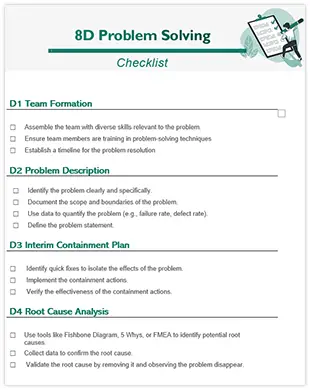

8 Disiplines of Problem Solving (8D)

The 8D Problem Solving methodology is commonly known as “Eight Disciplines of Problem Solving” or simply “8D.” It is a structured, team-based approach to identifying, analyzing, and resolving problems, particularly in the areas of product quality and process efficiency.