Guide: Gemba Walk

-

Daniel Croft

Gemba, the core of Lean principles, represents “the real place” where work happens and value is created. Originating from Japanese management philosophies, Gemba emphasizes the importance of firsthand observation in manufacturing and other sectors. By going to the Gemba, managers leave their offices to engage with the processes and people directly involved in value creation.

This practice reveals the reality of workflows versus their theoretical designs, uncovering inefficiencies, undocumented innovations, and areas ripe for improvement. It is an essential practice for leaders seeking to solve problems effectively and supports a culture of transparency and continuous improvement.

The term “Gemba” comes from the Japanese and translates to “The real place” in English, others refer to it as “the scene of the crime” as to go “Gemba” is to go to the place where the problem occurs (the crime). Gemba is essentially the place where the most critical activities in the value-creation process take place. In a manufacturing business, this is usually the shop floor or production facility.

Gemba is not just a physical location, but it is a focus for improvement activities. Going Gemba mean you can observe firsthand how the process is actually happening vs the ideal state and the current state of the process. Standard operating procedures and other documents may say how a process “should” be done, but it is important to see in reality how they are actually being done.

For various reasons, operators could do things differently to standard processes, such as workarounds and shortcuts to save time, or it could be that an unofficial method is actually better but has not been captured or documented. Management are unable to get this sort of insight into the processes by staying in their offices so going to Gemba and conducting Gemba walks is vital to improvement.

Gemba is a key tool use in business problem-solving and should be considered a key method applied in any problem-solving situation. Here’s how Gemba helps with problem-solving:

When observing a process during Gemba, it is not a passive activity. It is about actively looking, understanding, and questioning. You look at a workflow, the worker interaction, the performance of the machine and other elements to understand the process on a deeper level.

Sometimes operations occur so fast it may be difficult to understand all the process elements. Therefore, you may need to watch the process multiple times, but we recommend you record the process as it happens so you can watch it back and analyze it in great detail and also refer to elements of it when taking action later.

Once you have observed, the next step is to understand. This is where you’ll ask “why” a lot. Why is a process done this way? Why is there a bottleneck here? Understanding involves both analytical thinking and empathy.

A key method for understanding the answer to these questions can be to use the 5 Whys method. It might seem simple to keep asking why, but it is very effective at getting to the root cause of problems.

Once you have observed and understood, the next step is action. This could mean implementing a change immediately if it’s straightforward and the solution is clear. For complex issues, this could mean taking your observations back for further analysis.

If you are looking to do a Gemba walk it is important to follow a structured process to ensure it is as effective as possible, in this guide we will explain how to prepare, what to do during the walk and actions after the walk.

Choosing the right area or process to focus on is the first critical step in a Gemba walk. Make your selection based on performance indicators, employee feedback, or areas that have recently undergone changes. This is where you will likely find the greatest opportunity for improvement.

When selecting the area also consider the following:

Next, you should set clear objectives for the walk, rather than looking at a process and hoping something jumps out at you. Clear objectives set the stage for a focused Gemba walk. Are you trying to eliminate bottlenecks, improve safety, or enhance productivity?

Tips:

Observing involves more than just looking around; it demands your full attention to detail. During the walk you may use tools a techniques such as:

The Gemba walk isn’t just an observational activity; it’s also an opportunity for dialogue, and you should ask the operators in the area questions such as:

When asking the question, make sure that you take notes. Documentation is key for post-walk analysis and for sharing your findings with others.

Note-Taking Tips:

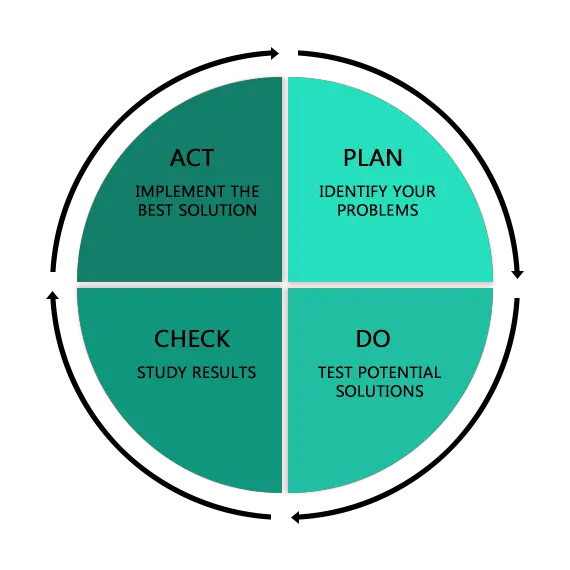

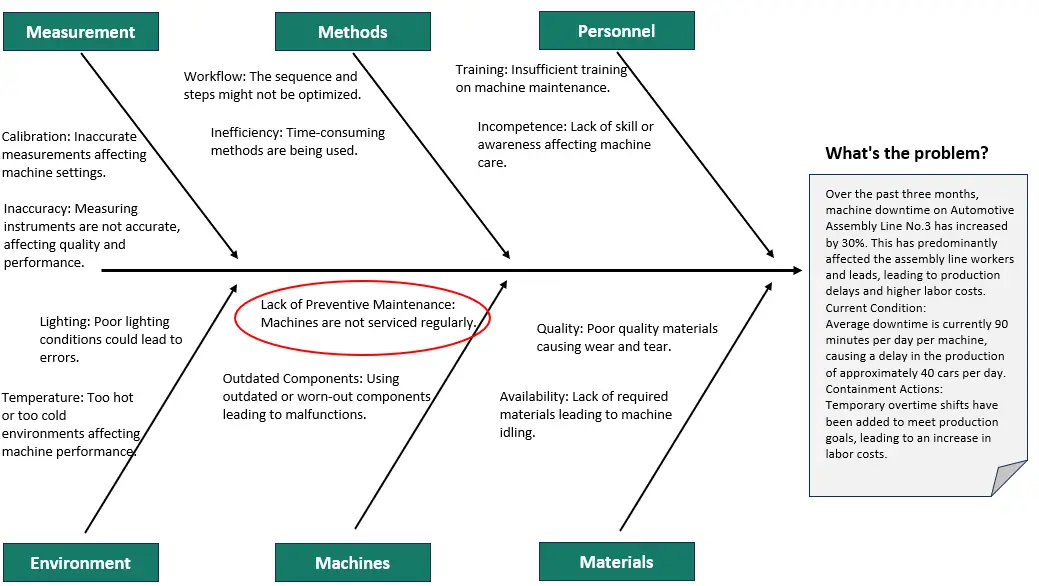

Once the walk is over, it’s time to work through your notes and any other data you’ve collected. Analysis can then be done on this using a range of tools depending on what the issues are that were identify you could use the following:

Based on your analysis, you’ll need to implement the necessary changes. When implementing the changes ensure that you do the following:

After implementation, it’s crucial to go back and see if the changes made have had the desired effect.

Follow-Up Tips:

And that is how to conduct a Gemba walk that results in implementing improvements.

So now that you know what a Gemba walk is, how to do one, etc. why should you do one?

Conducting gemba walks provides real-time problem identification. It helps to understand and identify the issues as they occur and take immediate action to correct them.

Conducting gemba walks directly improves employee engagement which can boost morale and foster a culture of continuous improvement. If you take action against issues and concerns operators have, they are likely to raise future issues and care more about what they do, and they know you observe and care too.

Gemba walks also improve decision-making as leaders are better informed of what is happening and why it is happening before deciding to make changes to a process they do not fully understand.

In the search of operational excellence, Gemba walks stand out as a transformative practice. By providing a clear view of on-the-ground operations, they enable real-time problem identification and deepen leaders’ understanding of the actual challenges facing their teams. This engagement is not just about spotting issues but also about valuing the insights of those who work with the processes every day.

Gemba fosters a two-way dialogue that enhances employee morale and drives a culture of continuous improvement. Furthermore, it sharpens decision-making, ensuring that leaders’ choices are informed by the nuanced realities of their operations. Through Gemba, businesses can achieve a harmonious blend of people-centric leadership and process efficiency.

A: Gemba is a Japanese term that translates to “the real place” or “the actual place.” It refers to the physical location where work is performed or where value is created, such as a factory floor, a construction site, a retail store, or any other operational environment.

A: Gemba is a key concept in various improvement methodologies, such as Lean and Six Sigma. It emphasizes the importance of going to the actual place where work happens to gain insights, gather data, and make informed decisions. By observing and engaging with the Gemba, organizations can identify and address issues, improve processes, and enhance overall performance.

A: Practicing Gemba offers several benefits. It helps managers and leaders better understand the work being done, the challenges faced by employees, and the overall flow of operations. By actively engaging in Gemba, organizations can identify waste, inefficiencies, and opportunities for improvement, leading to better problem-solving, higher quality, increased productivity, and enhanced employee engagement.

A: Gemba can be applied to various industries, including manufacturing, healthcare, service sectors, and more. In manufacturing, Gemba involves observing the production line, identifying bottlenecks, and streamlining processes. In healthcare, it involves going to the patient’s bedside to understand their needs and improve care delivery. Similarly, in the service sector, Gemba can involve visiting customer service centers, call centers, or retail locations to improve service quality.

A: Common practices in Gemba include direct observation of work processes, engaging in conversations with employees to understand their perspectives and challenges, collecting data and metrics related to performance and quality, and making decisions based on real-time information gathered from the Gemba. It is essential to adopt a non-judgmental and open-minded approach while practicing Gemba to foster collaboration and continuous improvement.

A: Organizations can encourage Gemba thinking by creating a culture that values and promotes direct observation and employee engagement. This can be achieved through regular Gemba walks, where managers and leaders visit the workplace to observe and interact with employees. Providing training and resources on Gemba methodologies, empowering employees to identify and solve problems, and recognizing and rewarding Gemba-driven improvements also contribute to fostering a Gemba mindset.

A: Implementing Gemba can face challenges, such as resistance to change, lack of awareness or understanding about the concept, and time constraints. Overcoming these challenges requires leadership commitment, effective communication, and employee involvement. It is important to address any skepticism, provide training and support, and demonstrate the value of Gemba through successful case studies and tangible results.

A: While Gemba is traditionally associated with physical workspaces, its principles can be adapted to virtual or remote work environments. In a virtual setting, Gemba can involve observing virtual meetings, analyzing online collaboration platforms, or engaging in discussions with remote team members to understand their challenges and find opportunities for improvement. The key is to focus on the “real place” where work is being done, regardless of its physical or virtual nature.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website www.learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.