8 Wastes – TIMWOODS Template

Subject: Template

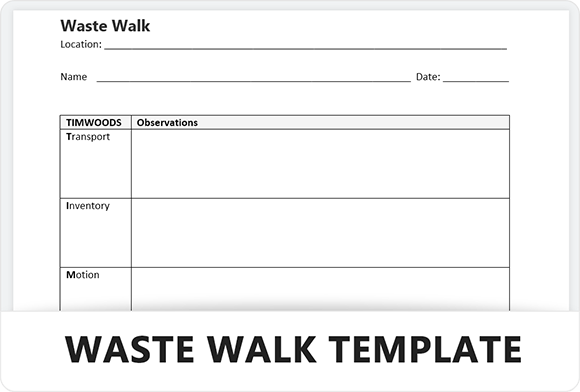

Waste Walk Template

The TIMWOODS acronym stands for Transport, Inventory, Motion, Waiting, Over-processing, Over-production, Defects, and Skills. These are known as the “8 Wastes” in Lean Six Sigma, which is a methodology for improving efficiency and eliminating waste in business processes. A waste walk is a way of identifying these wastes in a process by physically observing and analyzing the process.

Using the TIMWOODS waste walk identification sheet can help you to identify potential wastes and the types of wastes that need to be addressed in your processes. The sheet comes pre-made with the 8 wastes listed, so you can use it to guide your observations and identify any areas where waste is occurring.

Free Download

Download our Free Microsoft Word Lean Six Sigma 8 Wastes (TIMWOODS) waste walk identification sheet and identify potential wastes and the types of wastes in your processes that need to be addressed. This template comes pre-made with the TIMWOODS 8 wastes: Transport, Inventory, Motion, Waiting, Over-processing, Over-Production, Defects and Skills.

This can be used by handing out to process operators to identify wastes and issues with the current process to be addressed, making the processes more lean and efficient.

Learn more about the 8 Wastes waste walk sheet by clicking here.

Details

Features

Requirements

Training Information

Images

Features

This template is a simple word document that comes with the standard 8 process related wastes as sections including:

- Transport

- Inventory

- Motion

- Waiting

- Over-processing

- Over-Production

- Defects

- Skills

Requirements

This template works on any recent Microsoft Word software, including Office 365.

Training Information

The concept of the eight wastes comes from Lean Six Sigma, a methodology for improving efficiency and eliminating waste in business processes. The eight wastes are as follows:

Transport waste: This refers to unnecessary movement or handling of materials or products, such as moving them between different locations or transferring them between different people or machines.

Inventory waste: This is excess or unnecessary inventory that is not being used or is not needed.

Motion waste: This is unnecessary movement by people or machines, such as reaching for tools or equipment that are not needed or are not in the most efficient location.

Waiting waste: This is time spent waiting for something, such as waiting for a machine to become available or waiting for materials to be delivered.

Over-processing waste: This is any unnecessary steps or activities in a process, such as adding extra quality checks that are not necessary.

Over-production waste: This is producing more products than are needed or producing products before they are needed.

Defects waste: This is the expense of fixing or reworking defective products.

Skills waste: This is not utilising the full potential or skills of employees or not training employees to their full potential.

By identifying and removing these wastes, you can improve the efficiency and effectiveness of your processes, resulting in cost savings and increased output.

Why conduct a waste walk

The TIMWOODS 8 wastes waste walk is an extremely effective tool for identifying and eliminating waste in any process. Organizations that use the TIMWOODS methodology can reap the following benefits:

- Improved efficiency: Organizations can improve their operations’ efficiency and productivity by identifying and eliminating waste in processes.

- Increased profitability: Organizations can reduce costs and increase profitability by reducing waste and increasing efficiency.

- Better quality: Organizations can improve the quality of their products and services by identifying and eliminating waste, resulting in increased customer satisfaction and loyalty.

- Increased innovation: Organizations can foster a culture of innovation and continuous improvement by constantly seeking out and eliminating waste.

- Improved morale: By involving employees in the waste elimination process and giving them a voice in decision-making, organisations can improve employee morale and engagement.

- Better collaboration: The waste walk process necessitates cross-departmental collaboration and teamwork, resulting in improved communication and cooperation.

- Increased sustainability: By reducing waste, businesses can reduce their environmental impact and contribute to a more sustainable future.

Other common names for this template include: Timwood, Timwoods Waste, Tim Woods Lean, 8 Wastes Template and Timwoods 8 wastes

Related Templates

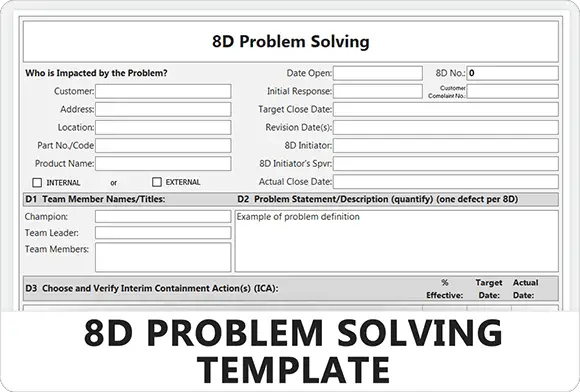

8D Problem Solving Template

8D Problem Solving Excel Template 8D Problem solving does not need to be an unstructured problem-solving processes with our 8D…

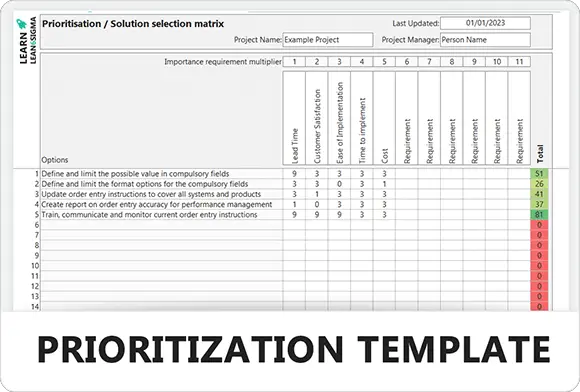

Prioritization Matrix Template

Prioritization Matrix Excel Template The Project Prioritization Matrix Excel Template, now available for free download. This template is designed to…

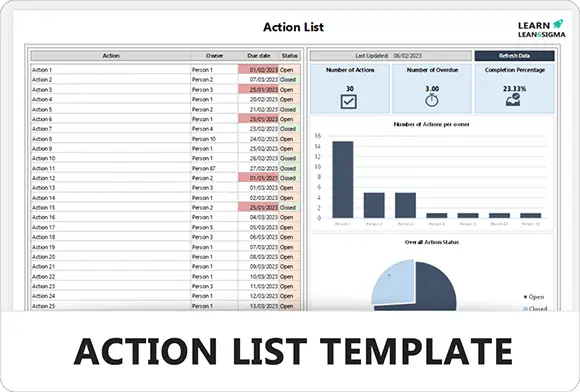

Action List Template

Action List Excel Template Our free to download Action List Excel Template is the perfect solution for organizing and tracking…