Implementing the Lean Principles in an Organization

Implementing Lean principles in an organization is a transformative process that requires strategic planning, dedicated involvement from all levels of staff, and a commitment to continuous improvement.

Step 1: Assessment and Planning

Before implementing the lean principles, it is important to understand and assess the current state of the business processes. This step would involve mapping out the current process with a process map or value stream map from start to finish and identifying inefficiencies, redundancies, and any steps that do not add value to the customer.

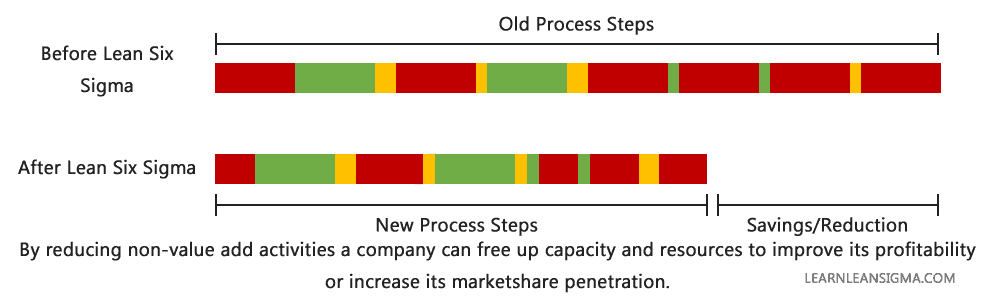

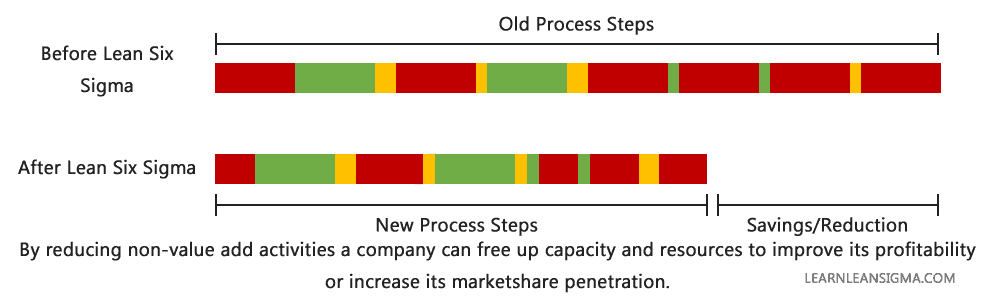

Take the following image as an example of the potential current and future states of the process. This theoretical visualisation is always the aim with the lean principles to reduce and remove as much waste as possible from the process and increase customer value.

Value add analysis example

Key to the success of the assessment and planning of implementing lean is engaging and involving all relevant stakeholders in the process, including leadership, employees and possible customers, to ensure there is a clear understanding of the process and to secure buy-in for lean initiates to follow.

Step 2: Training and Engagement

A vital element to the success of implementing lean in a business, and in my experience, often the most overlooked element, is training and engagement. Educating employees about lean principles and methodologies is important. Furthermore, this should involve more than just theoretical knowledge but also practical insights into how these principles can be applied to their specific roles, making the role relevant to them.

The goal of training and education should be to develop a culture where lean thinking becomes natural to them. This includes problem-solving, waste reduction, and continuous improvement.

This can be achieved by using engagement strategies such as workshops, seminars, and my favourite hands-on training sessions on real workplace problems. In effect, learners learn by doing while being guided by a qualified facilitator.

Step 3: Pilot Projects

Once you have the foundations of areas to be improved and a team that is trained and engaged, the next step is to start improving with small pilot projects. The key is to start small and expand as confidence and competency in the business grow.

Once those initial projects have been completed and stakeholders see visible results this will further help develop the culture of lean. Going big on projects that fail will only increase resistance to future projects.

Use these pilot projects as learning experiences. Gather data, analyze results, and understand what works and what doesn’t. After successful pilot projects, plan to scale up lean implementations to more extensive areas or other processes within the organization.

Step 4: Continuous Monitoring and Adaption

Step three was just the start of a never-ending cycle of improvement, therefore, step 4 is about continuous monitoring and adaption. The business should continue to regularly monitor the progress of lean initiatives and use key performance indicators (KPIs) to measure success and identify areas for improvement.

You should encourage feedback from employees and customers.This feedback is valuable for understanding the impact of changes and uncovering new areas for improvement. You should also be prepared to adapt strategies and approaches based on the results and feedback. Lean is about continuous learning and adaptation.

Step 5: Building a Lean Culture

Finally and constantly, you should continue to develop a lean culture in the business, as lean is not a quick fix but a long-term commitment that requires long-term effort and dedication.

To ensure this is successful, leadership must actively support and participate in lean initiatives and set an example for the rest of the organization. Additionally, employees should be empowered to take initiative, suggest improvements, and make decisions that align with Lean principles. Lean thinking should be integrated into every aspect of the organization, from daily routines to strategic decisions.