Guide: One Piece Flow

One Piece Flow streamlines production by moving items one at a time, reducing waste, improving quality, and enhancing efficiency. Discover the benefits and steps for successful implementation in your manufacturing process.

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

One Piece Flow, also known as Single Piece Flow or Continuous Flow, is a fundamental concept in Lean Manufacturing and Lean Six Sigma. It refers to the practice of moving one workpiece at a time between operations within a production process, rather than batching work. This approach is designed to improve efficiency, reduce waste, and enhance product quality. This guide will explain what One Piece Flow is, why it’s important, and how you can implement it in your processes.

What is One Piece Flow?

One Piece Flow, also known as Single Piece Flow or Continuous Flow, is a manufacturing philosophy and process where each item is produced and moved through the production process one piece at a time. This method is in contrast to traditional batch production, where products are made in groups or batches. In One Piece Flow, the goal is to streamline the production process so that each item progresses from start to finish without interruption, reducing delays and inefficiencies.

In a traditional batch production system, items are processed in groups. For example, a manufacturer might produce 100 units of a component, then move these units to the next stage of production, where they wait until the entire batch is completed before being processed further. This method can lead to significant waiting times, increased inventory levels, and potential quality issues, as defects in one batch can affect multiple units before being detected.

One Piece Flow aims to minimize these problems by ensuring that each workpiece moves through the production stages one at a time. This continuous flow means that as soon as one operation is completed, the item moves directly to the next stage. By doing so, the process becomes more efficient, and the production system can quickly adapt to changes and address issues as they arise.

Why is One Piece Flow Important?

One Piece Flow is essential for several reasons:

Reduced Waste

One Piece Flow minimizes the amount of work-in-progress (WIP) inventory. In traditional batch processing, large amounts of inventory can accumulate between stages, leading to wasted resources, space, and time. By moving items one at a time, One Piece Flow reduces excess inventory and the associated costs, leading to a leaner and more efficient production process.

Improved Quality

In a One Piece Flow system, each piece is inspected and processed individually. This means that any defects or issues can be identified and addressed immediately, preventing them from affecting subsequent units. Continuous inspection ensures higher quality products and reduces the likelihood of large-scale defects that are harder to correct.

Faster Throughput Time

Since each item is processed continuously, the overall production time is reduced. There are no waiting periods for batches to be completed, which means products move more quickly from start to finish. This leads to faster delivery times and improved customer satisfaction.

Greater Flexibility

One Piece Flow allows for greater flexibility in the production process. It is easier to adapt to changes in demand or production schedules when items are produced individually. If there is a sudden change in customer demand, the production process can quickly adjust without the need to rework large batches of products.

Better Use of Space

With less WIP inventory, there is more available space on the production floor. This can lead to a safer and more organized working environment. The reduction in clutter and excess materials also makes it easier to identify and address any issues that may arise.

How to Implement One Piece Flow

Implementing One Piece Flow in your production process involves several key steps. Each step is crucial for ensuring a smooth transition from batch production to a more efficient, single-piece production system.

Step 1: Assess Your Current Process

Before you can implement One Piece Flow, it’s essential to thoroughly understand your current production process. This involves mapping out each step in the production line to identify where bottlenecks and inefficiencies occur.

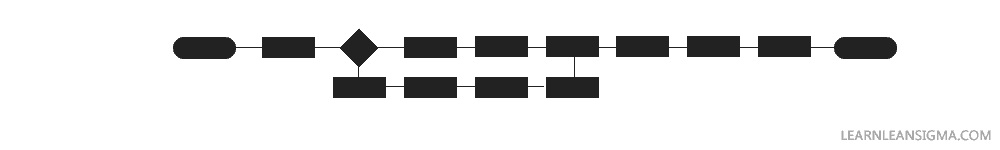

- Map the Process: Create a detailed process map that outlines every step of your production process from start to finish. This visual representation will help you see the flow of materials and work through your system.

- Identify Bottlenecks: Look for stages in the process where work accumulates or slows down. These bottlenecks are points where the flow is interrupted, causing delays and inefficiencies.

- Analyze Delays and Inefficiencies: Investigate the causes of delays and inefficiencies. This could be due to equipment downtime, waiting for materials, or unbalanced workloads.

Detailed sub process map

By thoroughly assessing your current process, you can identify areas that need improvement and prepare for the transition to One Piece Flow.

Step 2: Create a Flow Layout

The physical layout of your production area plays a significant role in enabling One Piece Flow. A well-designed layout facilitates the continuous movement of items through the production process.

- Design for Flow: Arrange workstations, equipment, and storage areas to support the sequential flow of materials. Ideally, workstations should be organized in a U-shape or in close proximity to minimize travel distances.

- Minimize Travel Distances: Position workstations and equipment so that materials and products do not have to travel long distances. This reduces handling time and potential damage.

- Eliminate Unnecessary Steps: Streamline the layout to remove any non-value-added activities. This might involve relocating equipment or combining steps to simplify the process.

A well-planned flow layout ensures that materials and products move smoothly and efficiently from one stage to the next.

Step 3: Balance the Workload

To prevent bottlenecks and ensure a smooth flow of work, it is crucial to balance the workload across all workstations.

- Analyze Task Times: Measure the time it takes to complete each task in the production process. This information will help you understand where imbalances occur.

- Redistribute Tasks: Adjust the distribution of tasks to ensure that each workstation has a similar workload. This might involve reallocating tasks or combining steps to balance the flow.

- Adjust Staffing Levels: Ensure that you have the right number of employees at each workstation to handle the workload efficiently. This may involve cross-training employees so they can assist in multiple areas.

Balancing the workload ensures that no single workstation becomes a bottleneck, maintaining a continuous flow of production.

Step 4: Implement Pull Systems

A pull system, such as Kanban, helps regulate the flow of materials and production based on actual demand rather than forecasts.

Introduce Kanban: Use Kanban cards or signals to control the movement of materials and products. Each workstation only produces what is needed for the next step, reducing overproduction and excess inventory.

Introduce Kanban: Use Kanban cards or signals to control the movement of materials and products. Each workstation only produces what is needed for the next step, reducing overproduction and excess inventory.- Set Up Pull Signals: Establish clear signals for when materials need to be replenished or when the next stage of production should begin. This ensures that work is pulled through the system based on customer demand.

- Monitor Inventory Levels: Keep a close eye on inventory levels to ensure that materials are available when needed without accumulating excess stock.

Implementing a pull system helps create a more responsive and efficient production process.

Step 5: Train Your Team

Educating your team about One Piece Flow and how to operate within this new system is critical for successful implementation.

- Provide Comprehensive Training: Teach employees about the principles of One Piece Flow, including the importance of quality checks at each step and how to identify and solve problems quickly.

- Emphasize Continuous Improvement: Encourage a culture of continuous improvement where employees are always looking for ways to enhance the process. This includes training on lean tools and techniques such as 5S, Kaizen, and root cause analysis.

- Ecourage Team Involvement: Involve employees in the planning and implementation process. Their insights and feedback are valuable for making practical improvements.

A well-trained team is essential for maintaining the efficiency and effectiveness of One Piece Flow.

Step 6: Monitor and Adjust

After implementing One Piece Flow, it’s crucial to continuously monitor the process and make adjustments as needed to optimize performance.

- Track Key Metrics: Measure cycle time, throughput, defect rates, and other relevant metrics to assess the performance of the production process.

- Identify Issues: Regularly review the data to identify any issues or areas for improvement. Look for trends or patterns that indicate potential problems.

- Make Adjustments: Be prepared to make adjustments to the process, layout, workload distribution, or training as needed. Continuous improvement is a fundamental aspect of One Piece Flow.

By regularly monitoring and adjusting the process, you can ensure that One Piece Flow remains effective and continues to deliver benefits.

Challenges and Solutions

Implementing One Piece Flow can present several challenges. Addressing these challenges effectively is crucial for a successful transition. Below are some common challenges and their solutions:

Challenge 1: Resistance to Change

Problem: Employees may resist the shift to One Piece Flow due to unfamiliarity with the new system or fear of increased workload. Change can be unsettling, and workers might be concerned about their ability to adapt to new processes and expectations.

Solution:

Involve Employees in Planning: Engage employees in the planning and implementation process from the start. Involving them in decision-making can help them feel more invested in the change and less resistant to it. Encourage them to share their insights and suggestions, as they have hands-on experience with the current process.

Provide Comprehensive Training: Educate employees on the principles and benefits of One Piece Flow. Offer thorough training sessions that cover new procedures, tools, and techniques. Training should also focus on problem-solving skills and the importance of quality checks at each step.

Communicate the Benefits: Clearly explain the benefits of One Piece Flow, such as improved efficiency, higher quality, and a safer working environment. Highlight how these changes will make their work easier and more satisfying in the long run.

Support and Encourage: Provide ongoing support and encouragement during the transition. Address concerns promptly and celebrate small victories to build confidence and momentum.

Challenge 2: Initial Investment

Problem: Reorganizing the production floor, balancing workloads, and implementing new systems may require an initial investment of time and resources. This can be a significant barrier for some organizations, particularly those with limited budgets.

Solution:

Evaluate Costs vs. Benefits: Conduct a thorough cost-benefit analysis to understand the long-term gains of implementing One Piece Flow. The improved efficiency, reduced waste, and higher product quality can lead to substantial savings and increased profitability over time.

Phased Implementation: Consider implementing One Piece Flow in phases to spread out the costs and make the transition more manageable. Start with a pilot project in one area of the production process, learn from it, and then gradually expand to other areas.

Seek External Support: Look for grants, subsidies, or other forms of financial assistance that may be available for companies adopting lean manufacturing practices. Consulting with lean manufacturing experts can also provide valuable insights and guidance.

Leverage Existing Resources: Maximize the use of existing resources where possible. For example, repurpose equipment, rearrange current layouts, and utilize cross-trained employees to minimize additional costs.

Challenge 3: Identifying Bottlenecks

Problem: It can be challenging to identify and eliminate bottlenecks within the production process. Bottlenecks slow down production and reduce overall efficiency.

Solution:

Use Value Stream Mapping (VSM): VSM is a powerful tool that helps visualize the flow of materials and information through the production process. By mapping out each step, you can identify where bottlenecks occur and understand their impact on the overall process.

Continuous Monitoring: Implement a system of continuous monitoring to regularly assess the performance of each stage in the production process. Use key performance indicators (KPIs) such as cycle time, lead time, and throughput to track progress and pinpoint issues.

Root Cause Analysis: When a bottleneck is identified, conduct a root cause analysis to determine the underlying cause. Tools such as the 5 Whys and Fishbone Diagram (Ishikawa) can help in identifying root causes.

Flexibility and Adaptability: Be prepared to make adjustments as needed. Flexibility is key in addressing bottlenecks. This may involve redistributing tasks, adding resources to specific areas, or implementing new technologies.

Conclusion

One Piece Flow is a useful approach to improving manufacturing efficiency, reducing waste, and enhancing product quality. By moving items through the production process one at a time, businesses can achieve significant improvements in speed, flexibility, and overall performance. Implementing One Piece Flow requires careful planning, training, and continuous monitoring, but the benefits make it a worthwhile focus for any organization looking to optimize its production processes.

References

- Ioana, A.D., Maria, E.D. and Cristina, V., 2020. Case study regarding the implementation of one-piece flow line in automotive company. Procedia Manufacturing, 46, pp.244-248.

- Ani, M., 2012. The effectiveness and impacts of one piece flow manufacturing technique into manufacturing industries. In 3a International Conference on Engineering and ICT (ICEI2012).

Q: What is One Piece Flow?

A: One Piece Flow is a manufacturing method where items are produced and moved through the production process one at a time, aiming to streamline operations and reduce waste.

Q: How does One Piece Flow improve product quality?

A: By inspecting each item individually during production, One Piece Flow allows for immediate identification and correction of defects, leading to higher quality products.

Q: What are the main benefits of One Piece Flow?

A: The main benefits include reduced waste, improved quality, faster throughput time, greater flexibility, and better use of space on the production floor.

Q: What challenges might I face when implementing One Piece Flow?

A: Common challenges include employee resistance to change, initial investment costs, and identifying bottlenecks in the production process.

Q: How can I start implementing One Piece Flow in my organization?

A: Begin by assessing your current process, creating a flow layout, balancing workloads, implementing pull systems like Kanban, training your team, and continuously monitoring and adjusting the process.

Author

Daniel Croft

Daniel Croft-Bednarski is a Continuous Improvement Manager with a passion for Lean Six Sigma and continuous improvement. With years of experience in developing operational excellence, Daniel specializes in simplifying complex concepts and engaging teams to drive impactful changes. He shares his expertise through LearnLeanSigma.com, offering tools, guides, and insights to help others implement Lean methods effectively. Daniel is committed to cultivating a culture of improvement, across the industry, through practical resources, innovative strategies, and a hands-on approach to leadership.

View Posts Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates.