Guide: 5S

Lean 5S is an organizational tool for efficiency and safety in workplaces, consisting of Sort, Set in order, Shine, Standardize, and Sustain, with a focus on continuous improvement and foundational lean manufacturing.

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

⚡️

5S TL;DR – read in 60 s

- 5S = Sort, Set in Order, Shine, Standardise, Sustain – lean housekeeping born at Toyota.

- Why care? Cuts search & motion waste, frees space, lifts safety, quality & morale.

- ROI: 10–30 % productivity gains within weeks; gateway to Kaizen, Kanban, TPM.

- Road-map: Kick-off → Red-tag sort → Visual layout → Daily clean/inspect → Photo standards → Weekly audits.

- Quick wins: Start small, involve operators, use before/after shots, link audit scores to KPIs.

- Many plants add a 6th Safety “S” so hazards disappear with the clutter.

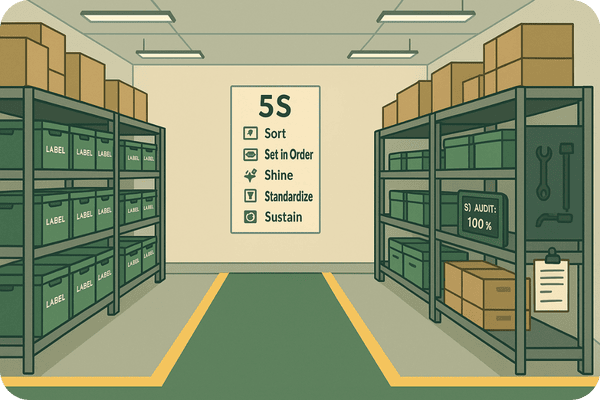

5S is a workplace organisation methodology for creating clean, safe, orderly, and high-performance work environments. It originated in Japan as part of Toyota’s production system in the 1950s and gets its name from five Japanese words – Seiri, Seiton, Seisō, Seiketsu, Shitsuke – which translate to Sort, Set in Order, Shine, Standardise, and Sustain. The method systematically reduces waste and optimises productivity by maintaining an orderly workplace. Implementation “cleans up” and organises the workspace in its existing configuration, and it is typically the first lean method which organisations implement.

In practical terms, 5S helps teams eliminate clutter, arrange tools for easy access, and embed cleanliness into daily work. If you’ve ever wasted time searching for a misplaced tool or navigated a cluttered, unsafe shop floor, 5S directly tackles those pain points. It also builds a foundation for continuous improvement – you can’t improve a process that you can’t see. Companies across manufacturing, warehousing, healthcare, and offices have embraced 5S to boost safety, quality, and efficiency. In fact, implementing 5S is often the easiest and most cost-efficient way to overcome disorganisation. (Before diving into how to implement 5S, let’s explore why it still matters today.)

Table of Contents

Why 5S Still Matters in 2025

More than six decades after its origin, 5S remains highly relevant in 2025 for organisations striving for operational excellence. The core principles of workplace organisation and cleanliness are timeless, but recent trends give 5S renewed importance:

Safety and ESG Alignment: A tidy, well-ordered workplace is a safer workplace. Fewer items on the floor mean fewer trip hazards and clearer emergency exits. In fact, a disorganised facility can put you in violation of OSHA or fire safety rules, risking costly fines or accidents. Many companies now link 5S to their ESG goals – it supports the “Social” element (employee well-being) and the “Governance” element (compliance through good housekeeping). Some even expand 5S to 6S (adding Safety) to emphasize this. By cutting clutter and waste, 5S also contributes to environmental goals (less scrap, more recycling).

Safety and ESG Alignment: A tidy, well-ordered workplace is a safer workplace. Fewer items on the floor mean fewer trip hazards and clearer emergency exits. In fact, a disorganised facility can put you in violation of OSHA or fire safety rules, risking costly fines or accidents. Many companies now link 5S to their ESG goals – it supports the “Social” element (employee well-being) and the “Governance” element (compliance through good housekeeping). Some even expand 5S to 6S (adding Safety) to emphasize this. By cutting clutter and waste, 5S also contributes to environmental goals (less scrap, more recycling).

Productivity and Cost Savings: Disorganisation costs time and money. Every minute spent hunting for a tool or reordering an item you already have is wasted. 5S tackles these inefficiencies head-on. A typical 5S frees up significant floor space (often 30–50%) by clearing out junk. In one case, a hospital operating room increased available space by 68% and cut infection rates after 5S. These 5S before and after gains mean lower operating costs and a smoother workflow.

Foundation for Lean & Continuous Improvement: 5S is widely considered the foundation of a Lean enterprise. It creates the stable, standardised environment needed for advanced techniques like Kanban, Just-in-Time, or Six Sigma. If you are disorganised, you don’t really know your baseline – so process improvements won’t stick. By implementing 5S, organisations enable accurate measurements and a culture of Kaizen. This is as true in 2025 as ever: whether you’re adopting Industry 4.0 tech or going for ISO certification, the discipline of 5S still underpins consistent results.

Employee Engagement and Morale: A clean, well-organised workplace tends to boost employee morale and ownership. Workers take pride in a tidy work area and face less frustration from daily obstacles. Case studies have noted improved staff attitudes and enthusiasm after 5S initiatives. In 2025’s competitive job market, involving employees in 5S (through idea generation, red-tagging, and audit teams) can also enhance engagement. People appreciate when their suggestions make their own work easier, and a successful 5S program often becomes a point of team pride.

In short, 5S still matters because it delivers safety, efficiency, and quality improvements with minimal investment. It’s also a gateway to a culture of continuous improvement. Next, we’ll break down the five “S” steps and then guide you through implementing 5S step by step in your organisation.

The Five “S” Explained

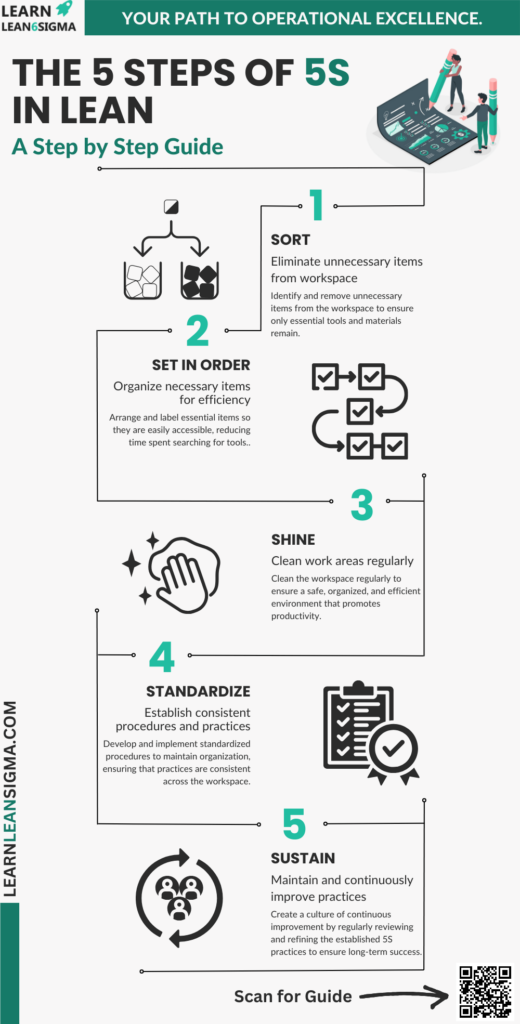

The name 5S comes from five Japanese words that all start with “S.” In English, they translate to Sort, Set in Order, Shine, Standardise, and Sustain (often called the “5S methodology” or “5S steps”). Let’s look at each “S,” its purpose, and how to execute it, along with a simple checklist for each. (Imagine a before-and-after slider image for each step to visualize the transformation.)

Sort (Seiri)

Goal: Eliminate everything that is not truly needed in the work area. Sorting separates the essential from the expendable. By removing clutter, you uncover the items, space, and information that actually matter.

What to Do: Go through the target area and identify tools, materials, equipment, or paperwork that are not required for current operations. Ask: “Do we need this? When was it last used?” If an item is unused, expired, or unnecessary, remove it. Use a red tag system for items that are questionable – tag them and move them to a holding area. As you Sort, dispose of trash, obsolete parts, and redundant supplies. Encourage the team to take “before” photos of the area to document the starting point.

Checklist:

Remove all unneeded items from the area (old tools, scrap, excess inventory, broken equipment).

Red-tag items of uncertain need and relocate them for evaluation.

Free up floor space and work surfaces by clearing out clutter (aim for ~30% space gain as a benchmark).

Take “after” photos to compare the improvement (for morale and audit records).

![Guide: 5S 4 Sort (Seiri) Goal: Eliminate everything that is not truly needed in the work area. Sorting separates the essential from the expendable. By removing clutter, you uncover the items, space, and information that actually matter. What to Do: Go through the target area and identify tools, materials, equipment, or paperwork that are not required for current operations. Ask: “Do we need this? When was it last used?” If an item is unused, expired, or unnecessary, remove it. Use a red tag system for items that are questionable – tag them and move them to a holding area. As you Sort, dispose of trash, obsolete parts, and redundant supplies. Encourage the team to take “before” photos of the area to document the starting point. Checklist: Remove all unneeded items from the area (old tools, scrap, excess inventory, broken equipment). Red-tag items of uncertain need and relocate them for evaluation. Free up floor space and work surfaces by clearing out clutter (aim for ~30% space gain as a benchmark). Take “after” photos to compare the improvement (for morale and audit records). [INSERT slider image pair – a cluttered workspace before Sort vs. tidy after Sort]](https://www.learnleansigma.com/wp-content/uploads/2023/05/LLS-Image-Sort-Before-and-After.png)

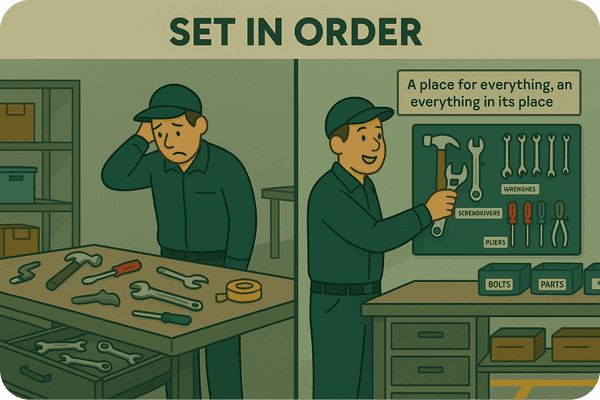

Set in Order (Seiton)

Goal: Arrange and label everything in the optimal place for efficient workflow. Once the unnecessary items are gone, organise whatever remains so that anyone can find what they need in 30 seconds or less. The motto here is “a place for everything, and everything in its place.”

What to Do: Decide the proper location for each remaining item based on its point-of-use. Store frequently used tools near where they are needed; place infrequently used items further away. Arrange the workspace so that work flows with minimal extra motion. Implement visual management: label shelves and containers, use color-coded zones, and mark outlines on the floor for equipment, bins, and work areas (for example, use shadow boards for tools and tape to mark aisles). The goal is that anyone can find any needed item in 30 seconds or less, and see when something’s missing.

Checklist:

Assign a “home” for each item – consider ease of access and ergonomics (e.g. heavy items on waist-high shelves).

Label all storage locations, drawers, and containers clearly (using words or pictures).

Use floor markings or signs to define work areas, equipment positions, and travel paths (outline tool placement, mark forklift lanes, etc.).

Arrange items by frequency of use (often-used within arm’s reach; rarely-used farther away).

Ensure every item has a clear, visible address so it can be returned to its spot after use.

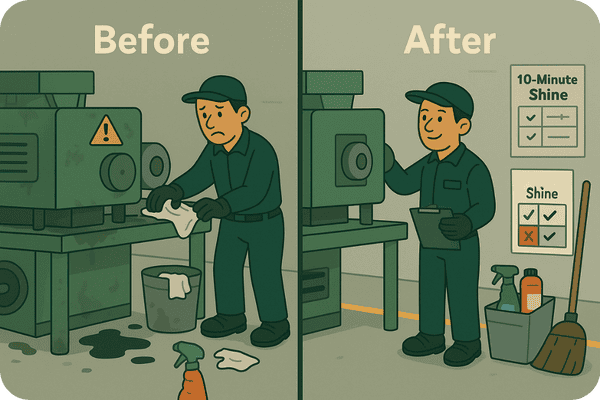

Shine (Seiso)

Goal: Clean the workspace and equipment thoroughly – and keep it clean daily. “Shine” means more than a one-time deep clean; it integrates cleaning into regular work as a form of inspection and preventive maintenance.

What to Do: Sweep, scrub, dust, and polish everything in the area – floors, machinery, workstations, and storage units. Remove all grime and debris. While cleaning, inspect for issues like leaks, loose parts, wear, or safety hazards and address them (or report to maintenance). After the initial deep clean, establish daily cleaning routines (for example, each shift spends 10 minutes cleaning before handover). Provide cleaning supplies nearby to make it easy. The goal is to make “clean” the new normal, so any mess or abnormality is immediately noticeable.

Checklist:

Perform an initial deep clean of all surfaces, equipment, and hard-to-reach corners.

Inspect while cleaning – identify any leaks, damage, or safety issues (and log them for repair).

Eliminate sources of dirt or dust (fix leaks, install covers or mats to contain debris).

Assign daily cleaning tasks (wipe down machines, empty bins, etc.) with a clear schedule.

Keep cleaning supplies handy and labeled (brooms, rags, solvents) to encourage ongoing Shine.

Standardise (Seiketsu)

Goal: Set standards and schedules to maintain the first three S’s uniformly. Standardise is about embedding Sort, Set in Order, and Shine into everyday procedures so the workplace doesn’t revert to the old ways. This creates a new “standard” of organisation.

What to Do: Develop simple routines and guidelines to maintain the first three S’s. Create daily or weekly 5S checklists for each work area and assign clear responsibilities (who does which task, and when). Document the agreed-upon locations for items with a 5S map or photos showing the standard layout. Use consistent labelling and color-coding across the site so everyone follows the same conventions. Integrate 5S duties into regular work and training – make following these standards part of the job, not an extra chore.

Checklist:

Create a 5S schedule (daily/weekly tasks) and assign responsibilities for upkeep.

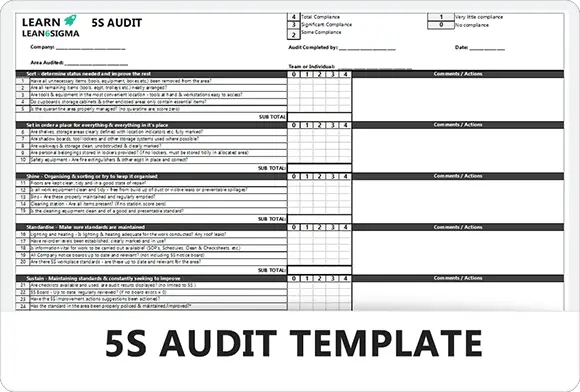

Develop a simple audit checklist for each area to regularly verify 5S conditions (see next section for an example).

Document the organised state: use photos or a 5S map to show the standard layout and storage locations.

Implement uniform labelling and colour standards site-wide (e.g. blue tape for finished goods, red tags for scrap).

Train all team members on the standards and incorporate 5S duties into regular work routines.

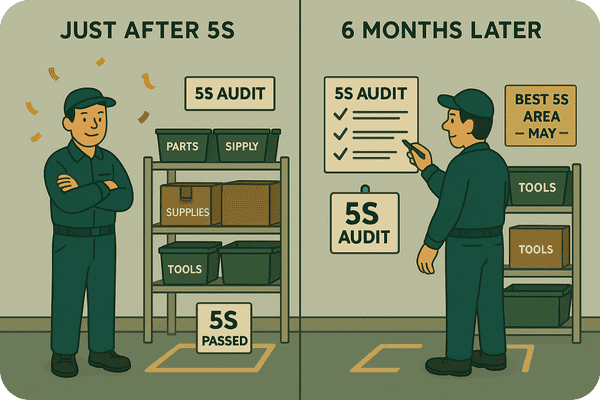

Sustain (Shitsuke)

Goal: Maintain the discipline and continuously improve. Sustain is about making 5S a long-term habit and culture, not a one-time project. This is often the hardest “S” because it requires self-discipline and management support over time.

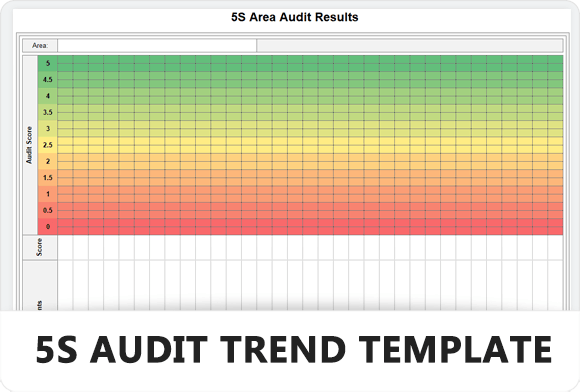

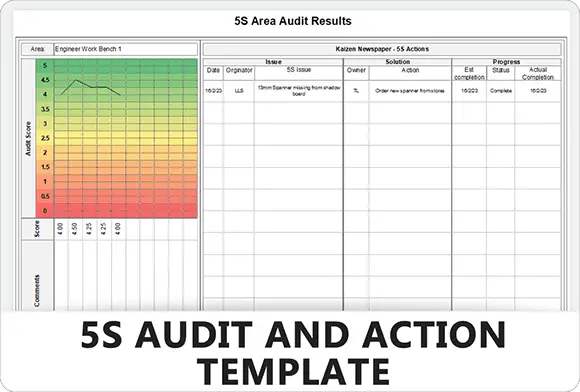

What to Do: Ensure ongoing emphasis so that old habits don’t return. Conduct regular 5S audits or inspections (e.g. weekly) using a standard checklist, and share the results with the team. Celebrate improvements – for instance, display before-and-after photos or recognise the “best 5S area” of the month. Management must keep reinforcing 5S (in meetings and Gemba walks) and quickly address any issues (like providing proper storage if new items appear). Make 5S engaging (some companies hold friendly competitions or give rewards for good 5S practices). Crucially, tie 5S into your continuous improvement process – treat it as a cycle to revisit whenever things change or new opportunities arise.

Checklist:

Conduct regular 5S audits with a standard checklist; share results and feedback with the team.

Hold periodic refresher trainings or Kaizen events to re-Sort and improve organisation as needs evolve.

Recognise and reward good 5S practice (team accolades, small rewards) to encourage adherence.

Ensure new employees are onboarded with 5S expectations from day one.

Leadership consistently “walks the talk” – leaders check and coach on 5S during routine walks, preventing slippage.

After going through these five steps, you can literally see the difference – tools are findable in seconds, floors are gleaming, and everything is in its rightful place. But successful 5S is more than these technical steps; it requires preparation and a structured plan to implement. In the next section, we’ll set you up for success before you launch 5S on the shop floor.

Preparation: Setting Up for Success

Implementing 5S in a workplace requires some groundwork to maximise the chances of success. Rushing in without preparation can lead to false starts or lack of buy-in. Here’s how to set up your 5S initiative for a smooth launch:

1. Secure Leadership Support and a 5S Champion: Make sure management is on board and visibly supportive. Explain the expected benefits (safety, efficiency, morale) in terms that align with company goals. Ideally, assign a 5S champion or coordinator – someone responsible for driving the effort, tracking progress, and keeping everyone motivated. Lack of leadership commitment is a top reason 5S initiatives fail, so get managers to actively participate (e.g. by kicking off events and providing resources).

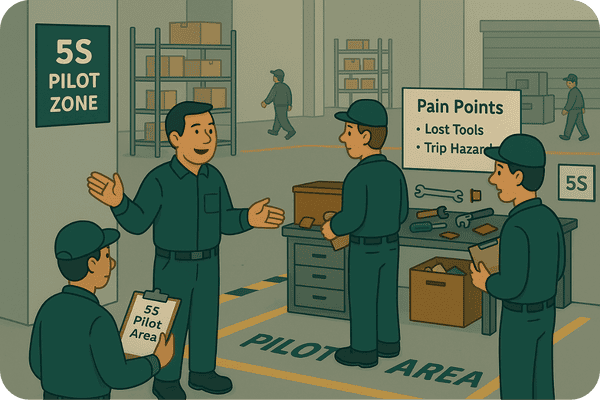

2. Select a Pilot Area: Don’t try to 5S the entire facility at once. Pick a pilot area to start – preferably one that is manageable in size and has clear pain points to fix (for example, a particular production cell, a storage room, or one office department). A good pilot area has a motivated team and obvious issues (e.g. frequent lost tools or safety hazards) that 5S can improve. Starting small allows you to learn and demonstrate results before scaling up.

3. Establish the Baseline: Before you begin, document the current state. Take photos of the area “as is,” and measure any relevant metrics (e.g. time spent looking for parts, accident rates, inventory levels, floor space used). You might conduct a baseline 5S audit to score how the area currently performs on each of the 5S pillars. This baseline will help you quantify improvements later and show the team tangible progress.

4. Create a 5S Map and Plan: Work with the team to envision the future organised state. Develop a simple 5S map or floor layout of the area, marking where key equipment and materials will belong after Set in Order. Plan what storage aids you might need (bins, tool racks, shadow boards, labels, shelving). Also map out the 5S process itself: schedule the Sort, Set, Shine activities and clarify who will do what. Having a written plan or checklist of tasks and timeline gives everyone clarity.

5. Gather Supplies: Assemble the materials you’ll need for the 5S event. Typical supplies include: red tags, tape (for floor marking), label makers or pre-printed labels, cleaning equipment (brooms, rags, cleaning solutions), shadow board materials (pegboards or foam for tool outlines), toolboxes or drawer organisers, signage, and personal protective equipment (gloves, etc.). Having everything on hand avoids delays once you start.

6. Train and Engage the Team: Before the hands-on work, educate the team about 5S principles. Hold a short training session to explain what 5S is, why the company is doing it, and how it benefits them. Show examples of 5S success (photos of a model area or a quick video). Emphasize that 5S is not about blaming messiness – it’s a team effort to improve everyone’s work life. Encourage questions and suggestions. This training gets everyone on the same page and generates buy-in.

7. Set Targets and a Kickoff Date: Define what success looks like for your 5S pilot. For instance, you might aim to cut the time to find a tool by 50%, achieve a certain audit score, or eliminate a known hazard. Setting specific goals gives the team something to strive for. Then schedule a kickoff – perhaps a “5S day” or series of workshop sessions where the team will perform Sort, Set in Order, and Shine together. Mark it on the calendar, communicate the plan, and build some excitement (you might even choose a fun team name or provide snacks during the event to keep energy up).

By laying this groundwork – leadership support, pilot selection, baseline measures, mapping, supplies, training, and clear goals – you create the conditions for a successful 5S implementation. Good preparation ensures that once you start the actual 5S steps, everyone is aligned and equipped to make lasting changes.

Conclusion

In conclusion, implementing 5S is a key first step toward lean manufacturing and Six Sigma implementation. The method includes sorting the area, setting it in order, cleaning (shine), setting standards, and sustaining 5S with audits and training.

As a result, the workplace is rewarded with benefits such as improved safety, time savings from not needing to look for equipment, and a boost to quality and morale, to name a few.

5S is not a one-time set-it-and-forget-it activity; it is an ongoing commitment to a way of working that must be maintained over time.

References

American Society for Quality (ASQ), n.d. What is 5S?. [online] Available at: https://asq.org/quality-resources/lean/five-s [Accessed 20 May 2025].

iSixSigma, n.d. The 5S System: Sort, Set in Order, Shine, Standardize and Sustain. [online] Available at: https://www.isixsigma.com/dictionary/5s/ [Accessed 20 May 2025].

Hirano, H., 1996. 5 Pillars of the Visual Workplace: The Sourcebook for 5S Implementation. Portland, OR: Productivity Press.

Miller, J., 2018. Sustaining 5S: Keeping the Workplace Lean and Clean. Journal of Manufacturing Systems, 38, pp.45–52.

Ohno, T., 1988. Toyota Production System: Beyond Large-Scale Production. Portland, OR: Productivity Press.

Ravi, V. and Singh, R.K., 2015. Improving Warehouse Operations through 5S Methodology. International Journal of Lean Six Sigma, 6(3), pp.215–230.

Sahoo, S., 2019. A Case Study on Implementation of 5S in a Manufacturing Plant. International Journal of Engineering Research and Technology, 8(6), pp.114–120.

Srinivasan, M., 2020. Implementing Lean: Transforming an Engine Plant Using 5S and Visual Controls. In: Lean Management in Practice. 1st ed. New Delhi: McGraw Hill, pp.103–118.

Author

Daniel Croft

Daniel Croft-Bednarski is a Continuous Improvement Manager with a passion for Lean Six Sigma and continuous improvement. With years of experience in developing operational excellence, Daniel specializes in simplifying complex concepts and engaging teams to drive impactful changes. He shares his expertise through LearnLeanSigma.com, offering tools, guides, and insights to help others implement Lean methods effectively. Daniel is committed to cultivating a culture of improvement, across the industry, through practical resources, innovative strategies, and a hands-on approach to leadership.

View Posts