Taiichi Ohno: Toyota Production System

Taiichi Ohno, the pioneer of Lean Manufacturing, developed Just-In-Time and Kanban, revolutionizing production by minimizing waste, enhancing quality, and improving efficiency. His legacy continues to inspire operational excellence globally.

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

Taiichi Ohno is often hailed as the father of the Toyota Production System (TPS), a methodology that has revolutionized manufacturing processes worldwide. His pioneering work laid the foundation for what we now recognize as Lean Manufacturing. Ohno’s innovations, particularly the development of the Just-In-Time (JIT) production and Kanban system, have left an indelible mark on industries beyond automotive manufacturing. Understand Ohno’s life, his groundbreaking contributions, and the key concepts that continue to drive efficiency and excellence in production processes.

Early Life and Career

Born in Dalian, China, in 1912, Taiichi Ohno’s journey into the world of manufacturing began when he joined Toyota Automatic Loom Works after graduating from Nagoya Technical High School in 1932. Dalian, a vibrant port city in Northeast China, was then under Japanese control, providing a unique cultural backdrop to Ohno’s formative years. His education at Nagoya Technical High School equipped him with a solid foundation in engineering and technical skills, which he would later apply to his revolutionary work in manufacturing.

Early Career at Toyota Automatic Loom Works

Upon joining Toyota Automatic Loom Works, Ohno quickly established himself as a diligent and observant employee. The company, founded by Sakichi Toyoda, was known for its innovative approach to manufacturing automatic looms. Here, Ohno’s keen observation of inefficiencies and his relentless drive to improve became evident. He was particularly influenced by the work of Sakichi Toyoda, whose invention of the automatic loom was driven by a desire to eliminate waste and improve efficiency. Ohno’s early exposure to these principles would later shape his approach to manufacturing.

Transition to Toyota Motor Corporation

In the 1940s, Ohno transitioned to Toyota Motor Corporation, which had been founded by Kiichiro Toyoda, Sakichi’s son. This move marked a significant turning point in his career. At Toyota Motor Corporation, Ohno encountered a different set of challenges. The company was striving to compete with American automobile manufacturers, who had much larger production volumes and resources. This environment presented Ohno with the opportunity to apply and refine his ideas on efficiency and waste reduction on a larger scale. By the time he moved to Toyota Motor Corporation, Ohno was well-equipped to challenge and transform traditional manufacturing practices.

In the 1940s, Ohno transitioned to Toyota Motor Corporation, which had been founded by Kiichiro Toyoda, Sakichi’s son. This move marked a significant turning point in his career. At Toyota Motor Corporation, Ohno encountered a different set of challenges. The company was striving to compete with American automobile manufacturers, who had much larger production volumes and resources. This environment presented Ohno with the opportunity to apply and refine his ideas on efficiency and waste reduction on a larger scale. By the time he moved to Toyota Motor Corporation, Ohno was well-equipped to challenge and transform traditional manufacturing practices.

The Birth of the Toyota Production System

Challenges and Inspiration

The post-World War II era posed significant challenges for Japanese manufacturers. Limited resources and a struggling economy forced companies to innovate to survive. Toyota, in particular, faced stiff competition from American automobile manufacturers, who had the advantage of economies of scale. Inspired by the efficiency of American supermarkets, which stocked only what was needed based on customer demand, Ohno envisioned a production system that minimized waste and maximized efficiency. He also drew inspiration from the philosophy of his predecessors, particularly Kiichiro Toyoda and Sakichi Toyoda, who emphasized continuous improvement and the elimination of waste.

The post-World War II era posed significant challenges for Japanese manufacturers. Limited resources and a struggling economy forced companies to innovate to survive. Toyota, in particular, faced stiff competition from American automobile manufacturers, who had the advantage of economies of scale. Inspired by the efficiency of American supermarkets, which stocked only what was needed based on customer demand, Ohno envisioned a production system that minimized waste and maximized efficiency. He also drew inspiration from the philosophy of his predecessors, particularly Kiichiro Toyoda and Sakichi Toyoda, who emphasized continuous improvement and the elimination of waste.

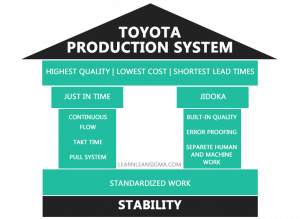

Core Principles of TPS

Elimination of Waste (Muda): Ohno identified seven types of waste (overproduction, waiting, transportation, extra processing, inventory, motion, and defects) and sought to eliminate them systematically. He believed that reducing these wastes would lead to more efficient and cost-effective production processes.

Continuous Improvement (Kaizen): Emphasizing small, incremental changes rather than large-scale overhauls, Kaizen became a cornerstone of TPS. Ohno encouraged workers to continually seek ways to improve their work processes, fostering a culture of perpetual improvement and innovation.

Respect for People: Ohno believed that empowering employees and fostering a culture of respect and collaboration were essential for sustained improvement. He implemented practices that encouraged employee involvement in problem-solving and decision-making, recognizing that those closest to the work often had the best insights into improving it.

Just-In-Time Production

Concept and Implementation

One of Ohno’s most significant contributions was the development of the Just-In-Time production system. The JIT philosophy centers around producing only what is needed, when it is needed, and in the amount needed. This approach reduces excess inventory, minimizes waste, and enhances responsiveness to customer demand. JIT production requires precise coordination and timing, ensuring that materials and components arrive at the production line exactly when they are required.

Key Elements of JIT

Takt Time: This is the rate at which products must be produced to meet customer demand. By aligning production with takt time, companies can avoid overproduction and reduce waiting times.

Flow Production: Ensuring that production processes are smooth and continuous, minimizing stoppages and delays. This involves optimizing the layout of production facilities and the sequence of operations to ensure a seamless flow of materials and products.

Pull System: In contrast to the traditional push system, where production is based on forecasts, the pull system relies on actual demand, triggered by downstream processes. This approach helps prevent overproduction and reduces the risk of excess inventory.

Kanban System

Origins and Purpose

To facilitate JIT production, Ohno developed the Kanban system, a scheduling system that controls the logistical chain from a production point of view. The term “Kanban” means “visual card” in Japanese, and the system uses cards to signal the need for inventory replenishment. Kanban helps maintain a smooth flow of materials and ensures that inventory levels are kept at optimal levels.

To facilitate JIT production, Ohno developed the Kanban system, a scheduling system that controls the logistical chain from a production point of view. The term “Kanban” means “visual card” in Japanese, and the system uses cards to signal the need for inventory replenishment. Kanban helps maintain a smooth flow of materials and ensures that inventory levels are kept at optimal levels.

How Kanban Works

Visual Control: Kanban cards provide a visual indication of the need for materials, helping to maintain an efficient flow of goods. When a part is used in production, a Kanban card is sent to the supplier, signaling the need for replenishment.

Limiting Work-In-Progress (WIP): By controlling the amount of WIP, Kanban helps prevent bottlenecks and ensures that production processes are balanced. This is achieved by limiting the number of Kanban cards in circulation, which in turn limits the amount of inventory in the system.

Continuous Improvement: Like other aspects of TPS, the Kanban system encourages ongoing refinement and enhancement of processes. By regularly reviewing and adjusting Kanban cards and inventory levels, companies can continually improve their production efficiency.

Impact and Legacy

Influence on Global Manufacturing

The principles and practices developed by Taiichi Ohno have had a profound impact on manufacturing industries worldwide. Lean Manufacturing, derived from TPS, is now a standard approach for organizations seeking to improve efficiency and competitiveness. Sectors ranging from healthcare to software development have adopted Lean principles to streamline processes and deliver value to customers.

Recognition and Honors

Taiichi Ohno’s contributions have been widely recognized. He received numerous awards and accolades, including the Deming Prize, for his exceptional work in quality management. His books, such as “Toyota Production System: Beyond Large-Scale Production,” continue to inspire and educate new generations of practitioners and scholars.

Conclusion

Taiichi Ohno’s visionary work laid the foundation for modern manufacturing excellence. His development of the Toyota Production System, with its focus on Just-In-Time production and the Kanban system, has transformed industries and set new standards for efficiency and quality. Ohno’s legacy lives on in the continuous pursuit of perfection and the relentless drive to eliminate waste in all its forms.

Author

Daniel Croft

Daniel Croft-Bednarski is a Continuous Improvement Manager with a passion for Lean Six Sigma and continuous improvement. With years of experience in developing operational excellence, Daniel specializes in simplifying complex concepts and engaging teams to drive impactful changes. He shares his expertise through LearnLeanSigma.com, offering tools, guides, and insights to help others implement Lean methods effectively. Daniel is committed to cultivating a culture of improvement, across the industry, through practical resources, innovative strategies, and a hands-on approach to leadership.

View Posts