In competitive business environments, companies across all industries are under constant pressure to do more with less, less time, fewer resources, and tighter budgets. The need to optimize operations has never been greater. That’s where Process Cycle Efficiency (PCE) comes into play. This powerful metric not only helps you quantify how effectively your processes are running, but it also identifies where hidden waste might be lurking.

By understanding and measuring PCE, you gain a clear picture of how to streamline workflows, reduce non-value-added activities, and ultimately deliver better products or services to your customers.

What Is Process Cycle Efficiency?

Process Cycle Efficiency (PCE) is a lean metric that calculates the ratio of Value-Added Time (VAT) to the Total Lead Time (TLT) in any given process. Think of it as a spotlight on your entire workflow: it illuminates where value is truly being created and, more importantly, where time is being lost to non-value-added activities—such as waiting, unnecessary movement, or rework.

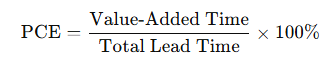

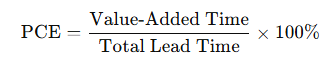

Mathematically, you can express PCE as:

PCE has its roots in methodologies like Lean Manufacturing and Six Sigma, which focus on eliminating waste and reducing variability. While it was originally popularized in the manufacturing sector, its principles are easily adaptable to virtually any industry, be it healthcare, software development, or service-based enterprises. Today’s businesses face increasing competition and customer demands for faster, higher-quality outputs. By highlighting inefficiencies in your processes, PCE remains a relevant and powerful metric that aids in driving continuous improvement, regardless of your field or area of expertise.

Process Cycle Efficiency Key Terms

Value-Added Time (VAT)

Value-Added Time refers to the portion of your process during which a product is being transformed or a service is being delivered in a way that directly benefits the customer. Essentially, it’s the “hands-on” time that contributes to the final outcome the customer cares about.

- Examples:

- The actual assembly of parts in a manufacturing line.

- Writing code that directly implements a new software feature.

- Performing a medical procedure that improves a patient’s health.

Non-Value-Added Time (NVAT)

Non-Value-Added Time is any activity that does not directly contribute to creating or enhancing the product or service from the customer’s perspective. These tasks often involve waiting, extra movements, or rework—essentially, time that adds cost but no real value.

- Examples:

- Idle time while waiting for materials or approvals.

- Excessive inspections that don’t uncover new issues.

- Transporting goods back and forth without need.

- Revising a product multiple times due to errors in earlier steps.

Total Lead Time (TLT)

Total Lead Time encompasses the entire duration of a process, from the initial request or start of production to the moment the final product or service is delivered. This total includes both value-added and non-value-added time.

Key Point:

Even if your Value-Added Time is relatively short, your Total Lead Time can balloon due to waiting times, transport, or other inefficiencies—making it crucial to track each step carefully.m Ford’s assembly line. From Lean to Six Sigma, the emphasis on reducing waste, standardizing processes, and optimizing workflows owes much to the legacy of this innovation.

The Formula for Process Cycle Efficiency

Formula

This calculation highlights the percentage of time in your overall process that is truly adding value.

Explanation

- Value-Added Time (VAT): The sum of all time spent on tasks that directly create value for the customer.

- Total Lead Time (TLT): The entire duration from the start to finish of the process, inclusive of both value-added and non-value-added activities.

- Result as a Percentage: Because the result is expressed as a percentage, it gives you an immediate sense of how efficient your process is in terms of value creation versus total time spent.

Typical Benchmarks

In many industries—especially manufacturing—PCE percentages often range between 10% and 15%. While that may seem low, even small improvements in PCE can generate substantial benefits. Reducing non-value-added steps, eliminating waste, or speeding up essential tasks can lead to:

- Lower operational costs

- Faster turnaround times

- Improved customer satisfaction

Whether you’re hitting 10% or 50%, continually monitoring and improving your PCE helps ensure your processes stay lean, effective, and competitive. the stage for a manufacturing revolution that continues to shape industries today. His story is a reminder that innovation isn’t just about big ideas—it’s about refining and adapting them for lasting success.

Step-by-Step Guide to Calculating PCE

Step 1. Identify the Process Scope

- Define Start and End Points: Clearly outline where the process begins and where it concludes. For instance, if you’re analyzing an order fulfillment process, the start might be when a customer places an order, and the end could be when the order is delivered.

- Determine Process Boundaries: Make sure everyone understands exactly what’s included in this scope. This avoids confusion about which tasks or sub-processes need to be measured.

Step 2. Map Out All Steps in the Process

- Create a Visual Flow: Document every step involved, from raw materials or initial service requests, all the way to final delivery.

- Use Process Mapping Tools: Software such as Lucidchart, Miro, or even simple flowchart templates can help you visualize each step. This provides a clear, shared view of the process for all stakeholders.

Step 3. Collect Time Data

- Measure or Estimate the Time Per Step: For each step in your mapped process, gather two key pieces of data:

- Processing Time – How long does the work actually take?

- Waiting or Idle Time – How much time do items spend in queues, on hold, or in transit?

- Ensure Accuracy: Wherever possible, observe the process in real time or pull data from operational logs to get reliable figures. This step lays the groundwork for accurate PCE calculation.

Step 4. Classify Each Step as Value-Added or Non-Value-Added

- Review Each Step: Determine which activities directly contribute to the end product or service (value-added) and which do not (non-value-added).

- Group and Total:

- Value-Added Time (VAT): Sum of all times spent on direct, beneficial work.

- Non-Value-Added Time (NVAT): Sum of all times spent on tasks that add no direct value, such as waiting, unnecessary inspections, or redundant movement.

Step 5. Calculate Total Lead Time

- Sum All Durations: Add up the duration of every step in the process, including both VAT and NVAT. This gives you the Total Lead Time (TLT).

- Capture Full Scope: Make sure to incorporate every touch point, even if some periods seem negligible, to avoid an incomplete picture of the process.

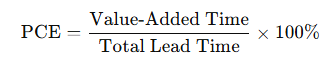

Step 6. Apply the PCE Formula

- Plug In Your Numbers: Once you’ve identified the total VAT and TLT, divide the former by the latter, then multiply by 100 to get a percentage.

- Example: If your total value-added time is 2 hours and your total lead time is 10 hours, your PCE would be: 2 divided by 10 X 100% = 20%

7. Interpret the Results

- Assess Your Efficiency: A high PCE indicates that a significant portion of your total lead time is devoted to value-added work. A lower PCE signals an opportunity to reduce waste and streamline processes.

- Identify Improvement Areas: Look for the biggest contributors to non-value-added time—long wait times, excessive rework, or inefficient transportation—and focus on eliminating or minimizing these.

- Continuous Improvement: PCE is not a one-and-done metric. Recalculate it after making changes to confirm whether those adjustments actually improve efficiency. Over time, consistent tracking and refinement can drastically enhance your operational performance.

Conclusion

Measuring Process Cycle Efficiency (PCE) allows you to pinpoint exactly how much of your total lead time is devoted to creating true value for the customer. By breaking down processes into value-added and non-value-added steps, you gain a clear roadmap for eliminating waste and making meaningful improvements. Even a modest boost in PCE can generate far-reaching benefits—shorter turnaround times, reduced costs, and higher customer satisfaction.

The key is to view PCE not as a one-off project but as a continuous improvement practice. Regularly track and recalculate your PCE to ensure that changes are truly making a positive impact. Encourage your team to look for areas where time is lost or rework is piling up, and make data-driven decisions on how best to optimize.

Ready to take action? Start by defining a single process you want to analyze, map out each step, and measure both processing and waiting times. Apply the PCE formula and see where you stand. From there, focus on eliminating non-value-added activities, and watch your efficiency soar. Over time, this relentless pursuit of improvement will not only enhance your bottom line but also strengthen your organization’s culture of excellence.