Guide: DMAIC

DMAIC is Six Sigma’s five-phase roadmap—Define, Measure, Analyse, Improve, Control—used to eliminate root causes, shrink variation, and embed sustainable gains in quality, cost, and customer satisfaction across any complex process.

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

DMAIC TL;DR — improve in 5 phases

- DMAIC = Define, Measure, Analyse, Improve, Control — the core Six Sigma roadmap for data-driven improvement.

- Purpose: eliminate root causes of defects and reduce process variation to hit critical customer CTQs every time.

- When to use: complex, recurring problems where you can quantify the gap and need statistical proof of improvement.

- 5 phases: Define the problem ► Measure current performance ► Analyse causes ► Improve with targeted solutions ► Control to lock gains.

- Success tips: build a tight project charter, validate the measurement system, attack the biggest X’s first, and hard-wire control plans.

- Toolkit: SIPOC, process maps, MSA, capability analysis, hypothesis testing, DOE, control charts—download templates from the guide.

The DMAIC methodology is a popular problem-solving framework that is used to drive process improvements and achieve measurable results. Businesses can improve efficiency, quality, and customer satisfaction by using a structured and data-driven approach to identify, analyze, and address issues.

28 Days of Lean Mastery –

Free Templates Inside

Every day you’ll get a proven Lean tool, a tip to apply it, and a downloadable template.

- ✅ Daily email with Lean tools

- ✅ Excel + printable templates

- ✅ Bite-sized lessons you can use

The DMAIC Steps

Step 1: Define

In step one of the DMAIC process, you are focused on defining, which involves defining all of the elements of the improvement process and is one of the most important stages as it lays the foundation for stages that follow and ensures the project goes on the right track.

By the end of the define stage, the project should have the following defined:

- Define the problem

- Defined goal

- Defined the process

- Identify the customers and their needs (VOC)

- Identify Stakeholders

- Define the project timeline

To do this effectively a range of tools need to be used such as the 5W1H Is/Is Not method to define the problem, SMART Targets for goal setting, Process mapping to define the process, Stakeholder Analysis to rank the stakeholders, etc.

All of these elements should be clearly laid out and supported with a project charter, which will be used to get sponsor support and stakeholder buy-in to support the problem.

Step 2: Measure

After successfully defining the problem you are looking to resolve or the process you want to improve, it is time to work on the measurement phase, which involves collecting data on the problem to verify what the problem is.

Within this you will work with a cross-functional team to initially create a data collection plan which will plan out what data is needed to verify the problem and also help with the analysis stage that comes next.

The data collection plan plans out what data will be collected, where it is collected from when it will be collected, the frequency, who will record it and the method. To get an in-depth understanding, take a look at the Data Collection Guide.

Once you have this data collected, you should be able to get a baseline measurement understanding of the process, which would be referred to as the current state.

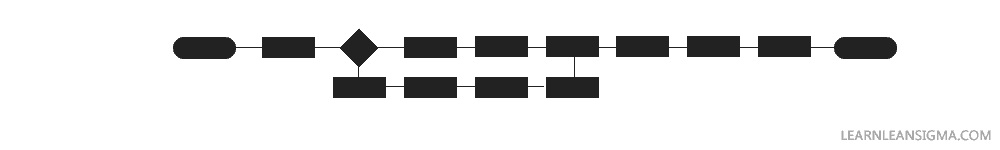

Another way the measure phase can be conducted is by creating a process map to define the process “as-is,” or the current state of how the process is being completed.

Detailed sub process map

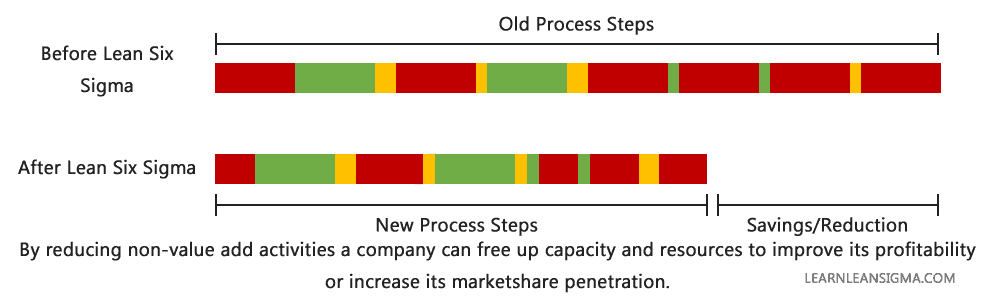

By mapping out the process, you can analyse the current state and later create the future state process map that will look to improve the process and remove waste from the process in relation the 8 Process Wastes

Value add analysis example

Step 3: Analyze

Following the collection of the data needed to understand the problem, the next step is to conduct analysis, which in Lean Six Sigma is a huge topic as there are many ways analysis can be done depending on the problem and the type of data that you have.

In the analysis phase, some of the methods that can be used include Fishbone Diagram, 5 Whys and FMEA for non-numerical data. However, for numerical data, the list of tools includes the following:

- Hypothesis Testing

- Anova

- Chi-Square

- Correlation Analysis

- Regression Analysis

- Pareto Chart

- Scatter Plot

- Box Plot

- Histograms

- Time Series Plot

We could not cover all of these methods within this guide. However, if you are looking to use one or more of these methods, consult our guides section to learn more about them and how to conduct the analysis.

This analysis is done to verify the root causes of problems, understand what is causing them, and direct the improvement team to know what action needs to be taken to address them.

DMAIC-Template-Example-Page-2

Step 4: Improve

After the analysis has been completed, and the root cause of the problem has been identified, the project team should conduct a brainstorming session to gather various potential solutions to the problem.

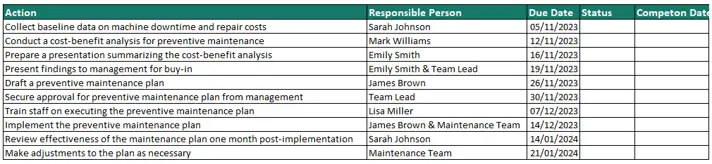

Once the brainstorming has been done and the solutions have been identified, the team should then create a plan for implementation. This will likely be in the form of an action plan that sets out what the actions are when they need to be done, and who will do them.

The plan will likely involve pilot testing the improvements by conducting small tests or trials and analyzing the results before full implementation. It is also common practice to conduct a cost-benefit analysis to evaluate if it is feasible to take full advantage of the potential solutions.

Step 5: Control

Once the improvements are in place, they need to be controlled and sustained to ensure that they are long-term solutions and not short-term ones, following the improvement and then reverting back to pre-improvement levels.

This is usually done using tools such as control charts that collect data at regular intervals to measure process performance, supported by updating documentation and standard operating procedures that confirm and formalize any changes to the process. It could also include updating any training to individuals involved with the process and regular audits of the process.

DMAIC-Template-Example-Page-3

DMAIC Template

If you are looking to use the DMAIC methodology you might find it useful to use the DMAIC project report template to structure and communicate your project to the business. Feel free to download it from the template section.

Conclusion

The DMAIC methodology is a proven, structured approach for process improvement that stands for Define, Measure, Analyze, Improve, and Control. As a backbone of Lean Six Sigma, it offers a comprehensive roadmap for problem-solving and optimizing business processes.

Starting with the ‘Define’ phase, the methodology emphasizes laying a strong foundation by setting objectives and assembling a team. The ‘Measure’ phase focuses on collecting relevant data to understand the current state. Then comes ‘Analyze,’ where the focus shifts to identifying root causes through a variety of analytical tools. ‘Improve’ involves brainstorming solutions and pilot testing, while the ‘Control’ phase ensures that improvements are sustainable over the long term. Altogether, DMAIC offers a complete, data-driven strategy for achieving measurable improvements in efficiency, quality, and customer satisfaction.

References

- Berardinelli, C.F., 2012. TO DMAIC or not to DMAIC?. Quality Progress, 45(11), p.72.

- De Mast, J. and Lokkerbol, J., 2012. An analysis of the Six Sigma DMAIC method from the perspective of problem solving. International Journal of Production Economics, 139(2), pp.604-614.

A: DMAIC stands for Define, Measure, Analyze, Improve, and Control. It is a structured problem-solving methodology used in Six Sigma to improve processes and reduce defects.

A: The purpose of DMAIC is to identify and address problems or inefficiencies in a process, leading to measurable and sustainable improvements. It provides a framework for problem-solving and continuous improvement.

A: The steps in DMAIC are as follows:

- Define: Clearly define the problem and project goals.

- Measure: Gather data and measure the current state of the process.

- Analyze: Analyze the data to identify the root causes of the problem.

- Improve: Develop and implement solutions to address the identified causes.

- Control: Establish control mechanisms to sustain the improvements made and prevent future issues.

A: No, DMAIC is a versatile problem-solving methodology that can be applied to various industries and processes, including manufacturing, service, healthcare, software development, and more. It is applicable wherever there is a need for process improvement and reducing defects.

Author

Daniel Croft

Daniel Croft-Bednarski is a Continuous Improvement Manager with a passion for Lean Six Sigma and continuous improvement. With years of experience in developing operational excellence, Daniel specializes in simplifying complex concepts and engaging teams to drive impactful changes. He shares his expertise through LearnLeanSigma.com, offering tools, guides, and insights to help others implement Lean methods effectively. Daniel is committed to cultivating a culture of improvement, across the industry, through practical resources, innovative strategies, and a hands-on approach to leadership.

View Posts