5 Methods of Problem Solving Every Lean Thinker Should Know

Ever feel like you’re playing whack-a-mole with workplace problems? Just when you fix one issue, another pops up—or worse, the same one returns! The real challenge isn’t just putting out fires but finding and eliminating the root cause so problems don’t come back.

That’s where structured problem-solving methods come in. In Lean and Continuous Improvement, guessing won’t cut it—you need data-driven, repeatable techniques to analyze, solve, and sustain improvements.

In this post, I’ll break down five essential problem-solving methods that help teams stop firefighting and start making real progress. Whether it’s a quality issue, efficiency challenge, or recurring defect, these tools will help you get to the bottom of it—and fix it for good.

1. 5 Whys Analysis – Digging Deep for Root Causes

One of the simplest yet most powerful problem-solving techniques is the 5 Whys Analysis. It’s exactly what it sounds like—asking “Why?” five times (or more) to uncover the real root cause of a problem.

How It Works

Rather than treating symptoms, this method helps identify the underlying issue. Here’s how to apply it:

- State the problem clearly. (e.g., “The machine keeps breaking down.”)

- Ask ‘Why?’ (e.g., “Why did the machine break down?”)

- Record the answer and ask ‘Why?’ again. (e.g., “Because the motor overheated.”)

- Repeat until you reach the root cause.

You might not always need exactly five “Whys”—sometimes fewer, sometimes more. The key is to stop when you find a cause you can control and improve.

Example: Solving a Machine Breakdown

Let’s say you’re dealing with frequent machine failures:

- Why did the machine stop? → The motor overheated.

- Why did the motor overheat? → It wasn’t properly lubricated.

- Why wasn’t it lubricated? → The maintenance schedule was missed.

- Why was the schedule missed? → The operator wasn’t trained on the new system.

- Why wasn’t the operator trained? → No standardized onboarding process exists.

Key Takeaways

- If we had stopped at the first or second “Why,” we might have just replaced the motor—a temporary fix.

- Instead, we found the root cause: a lack of standard training.

- Fixing this prevents future failures, rather than reacting every time the machine overheats.

When to Use 5 Whys

✅ Quick troubleshooting for recurring problems

✅ Issues with unclear root causes

✅ Process or system breakdowns

❌ Not ideal for complex, multi-factor problems (try a Fishbone Diagram instead!)

2. Fishbone Diagram – Visualizing Root Causes

Sometimes, a problem has multiple contributing factors, making it difficult to pinpoint the root cause. That’s where the Fishbone Diagram (also called the Ishikawa Diagram or Cause-and-Effect Diagram) comes in handy. It provides a structured, visual way to break down all potential causes of an issue.

How It Works

- Define the problem statement. Write the problem at the “head” of the fish.

- Identify major categories. Common ones include:

- Man (People) – Skill level, training, work habits

- Machine (Equipment) – Maintenance, technology, reliability

- Material (Supplies) – Quality, consistency, availability

- Method (Processes) – Procedures, standards, inefficiencies

- Measurement (Data) – Accuracy, frequency, relevance

- Environment – Workplace conditions, external factors

- Brainstorm potential causes. Under each category, list possible reasons the problem occurs.

- Analyze and prioritize. Identify the most likely causes and investigate further.

Example: Product Defect Issue

Let’s say your company is experiencing high defect rates in a product line. A Fishbone Diagram might look like this:

Problem: Increased product defects

- Man: Inexperienced workers, unclear instructions

- Machine: Aging equipment, poor maintenance

- Material: Supplier inconsistency, low-quality raw materials

- Method: No standardized process, lack of inspection

- Measurement: Inconsistent quality checks, faulty sensors

- Environment: Excess humidity affecting materials

Key Takeaways

- This tool maps out every possible cause rather than jumping to conclusions.

- It helps teams visualize connections between causes and effects.

- It’s particularly useful when multiple factors contribute to a problem.

When to Use a Fishbone Diagram

✅ Problems with multiple contributing factors

✅ Quality defects, process failures, or recurring production issues

✅ When 5 Whys alone isn’t enough to find the true root cause

❌ Not ideal for simple problems—it can overcomplicate a straightforward issue.

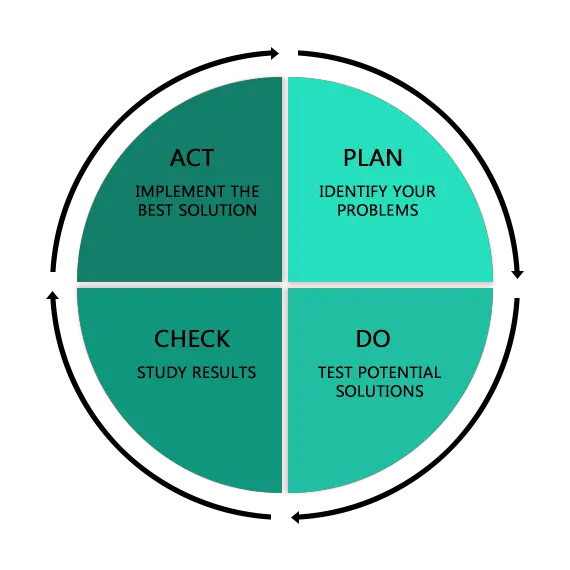

3. PDCA Cycle – The Lean Approach to Continuous Improvement

Solving a problem isn’t just about finding the cause—it’s about making sure your solution actually works and sticks. That’s where the PDCA Cycle (Plan-Do-Check-Act) shines. It’s a structured, repeatable method for testing, implementing, and refining solutions in a controlled way.

How It Works

The PDCA Cycle is a loop, meaning it can be repeated continuously to drive incremental improvements:

- Plan – Identify the problem, analyze the root cause, and develop a plan for solving it.

- Do – Implement the solution on a small scale (pilot test).

- Check – Measure the results and analyze whether the change was effective.

- Act – If successful, standardize the solution and apply it widely. If not, refine and restart the cycle.

Example: Reducing Order Processing Delays

Your company faces delays in processing customer orders, so you apply PDCA:

- Plan: You investigate and find that orders are getting stuck in approval bottlenecks. A new workflow reducing unnecessary approvals is proposed.

- Do: You test the new workflow in one department for two weeks.

- Check: Data shows processing time decreased by 30%, and customers are receiving orders faster.

- Act: You roll out the new workflow across the company and monitor for further improvements.

Key Takeaways

- PDCA ensures solutions are tested before full-scale implementation, reducing the risk of failure.

- It promotes a cycle of continuous improvement, refining processes over time.

- Small, controlled experiments help teams learn and adapt without major disruptions.

When to Use PDCA

✅ Process inefficiencies that need systematic improvement

✅ Situations where trial-and-error testing is required

✅ Problems that require ongoing adjustments

❌ Not ideal for urgent, one-time issues that need immediate fixes (try 5 Whys or 8D instead).

4. A3 Problem-Solving – A One-Page Blueprint for Action

When a problem requires a structured, well-documented approach, A3 Problem-Solving is the way to go. Developed by Toyota, this method provides a clear, concise, and visual way to analyze a problem, propose solutions, and track implementation—all on a single sheet of paper (hence the name “A3,” which refers to the paper size).

How It Works

A3 Problem-Solving follows a structured approach, often divided into seven key sections:

- Background – What’s the problem, and why is it important?

- Current Situation – Where do things stand now? Use data and visuals.

- Problem Analysis – What’s causing the issue? (Use 5 Whys or a Fishbone Diagram)

- Target Condition – What does success look like? Define measurable goals.

- Countermeasures – What solutions will address the root cause?

- Implementation Plan – Who will do what, and by when?

- Follow-up & Results – How will you measure success and sustain improvements?

Example: Reducing Changeover Times in Manufacturing

Your team struggles with long machine changeover times, delaying production. You create an A3 report:

- Background: Changeovers take 60 minutes, limiting output.

- Current Situation: Operators struggle with inconsistent procedures and missing tools.

- Problem Analysis: A Fishbone Diagram reveals that the main issue is a lack of standardized work and unorganized tooling.

- Target Condition: Reduce changeover time to 30 minutes.

- Countermeasures: Implement 5S principles to organize tools and create a step-by-step checklist for changeovers.

- Implementation Plan: Train operators, test the new process, and track cycle times.

- Follow-up: Measure and refine the process, ensuring standard work is followed.

Key Takeaways

- A3 forces teams to document their problem-solving process clearly.

- It encourages collaborative problem-solving, keeping everyone aligned.

- Visual elements (charts, graphs, diagrams) make it easy to understand at a glance.

When to Use A3 Problem-Solving

✅ Issues that require detailed analysis and documentation

✅ Problems that involve multiple teams or departments

✅ When a structured, repeatable approach is needed for future improvements

❌ Not ideal for quick fixes—this method requires thorough investigation.

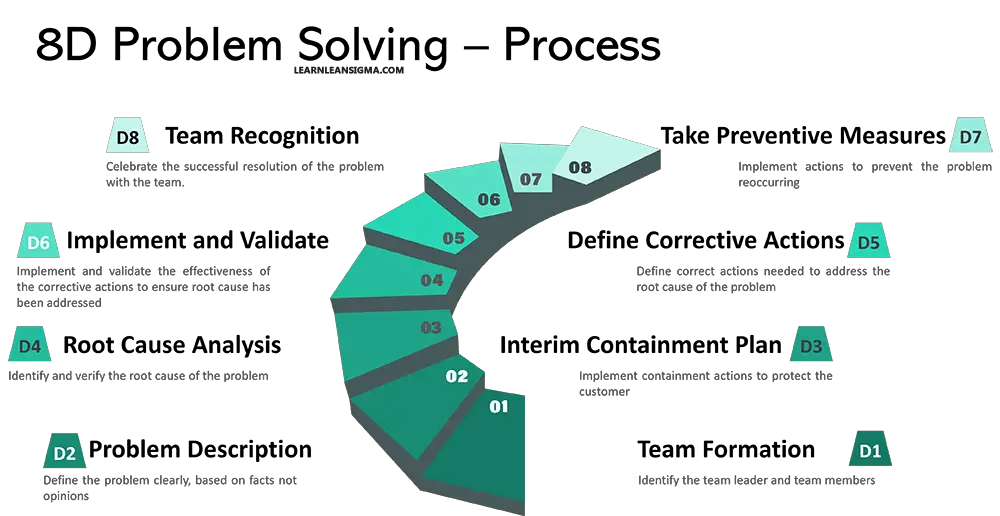

5. 8D Problem-Solving – A Systematic Approach for Complex Issues

When a problem is serious, recurring, or customer-impacting, you need more than a quick fix—you need a structured, team-based approach to eliminate the issue permanently. That’s where 8D (Eight Disciplines) Problem-Solving comes in.

Developed in the automotive industry, 8D is a step-by-step method for solving complex problems by identifying root causes, implementing corrective actions, and preventing recurrence.

How It Works

8D follows eight structured steps:

- D1 – Form a Team → Assemble a cross-functional team with the right expertise.

- D2 – Define the Problem → Describe the issue clearly, using data and evidence.

- D3 – Implement Containment Actions → Apply temporary fixes to stop the problem from worsening.

- D4 – Identify Root Causes → Use tools like 5 Whys and Fishbone Diagrams to pinpoint the source.

- D5 – Develop Permanent Solutions → Identify corrective actions that eliminate the root cause.

- D6 – Implement & Validate Solutions → Roll out fixes and ensure they work as expected.

- D7 – Prevent Recurrence → Standardize new processes, update training, and apply lessons learned.

- D8 – Recognize the Team → Document results and acknowledge contributions.

Example: Eliminating a Recurring Quality Defect

A customer reports that 20% of delivered parts have surface defects. Using 8D:

- D1: A team of engineers, quality specialists, and production managers is formed.

- D2: The team collects defect data and defines the scope of the problem.

- D3: Temporary inspections are added to prevent further defects reaching customers.

- D4: A Fishbone Diagram reveals the root cause—improper machine calibration.

- D5: A new calibration process is developed to prevent variation.

- D6: The process is tested and successfully reduces defects to 1%.

- D7: Calibration procedures are standardized, and staff training is updated.

- D8: The team documents findings and shares best practices across the company.

Key Takeaways

- 8D is best suited for serious, complex, or customer-impacting problems.

- It ensures temporary fixes are in place while root causes are fully investigated.

- The structured approach prevents recurrence and drives long-term improvements.

When to Use 8D Problem-Solving

✅ Customer complaints or safety issues

✅ High-risk, recurring, or business-critical problems

✅ When a detailed team-based approach is needed

❌ Not ideal for quick fixes or everyday process improvements (try 5 Whys or PDCA instead).

Choosing the Right Problem-Solving Method

Problem-solving isn’t about guessing or applying bandaid fixes—it’s about using the right tool for the right situation. Here’s a quick guide:

| Method | Best For |

|---|---|

| 5 Whys | Quick root cause analysis for simple problems |

| Fishbone Diagram | Complex issues with multiple contributing factors |

| PDCA | Continuous improvement and process optimization |

| A3 Problem-Solving | Documenting structured problem-solving efforts |

| 8D Problem-Solving | Serious, recurring, or customer-impacting problems |

The key to effective problem-solving is consistency and discipline. Whether you’re tackling a production issue, customer complaint, or efficiency challenge, these five methods will help you analyze, solve, and sustain improvements.

Conclusion

Problems are inevitable—but repeating the same mistakes isn’t. The difference between firefighting and sustainable problem-solving is using the right method to find and fix root causes, not just symptoms.

- For quick issues, use 5 Whys to dig deep fast.

- For complex problems, map out causes visually with a Fishbone Diagram.

- For continuous improvement, cycle through PDCA to refine solutions.

- For structured problem-solving, document your approach with A3 Thinking.

- For serious, recurring problems, apply the 8D Process for lasting change.

By mastering these five methods, you’ll stop chasing symptoms and start driving real, measurable improvements in your processes.

References

- Benjamins, V.R. and Fensel, D., 1998. Problem-solving methods. International Journal of Human-Computer Studies, 49(4), pp.305-313.

- Nilsson, N.J., 1971. Problem-solving methods in. Artificial Intelligence, 5.

- Fensel, D. and Motta, E., 2002. Structured development of problem solving methods. IEEE Transactions on Knowledge and Data Engineering, 13(6), pp.913-932.