Lean Mfg TL;DR — flow, no waste

- Lean Manufacturing streamlines value creation by attacking eight wastes and building continuous flow and pull.

- Why adopt? Cuts lead time, inventory, defects, and cost while boosting flexibility, capacity, and employee engagement.

- Core pillars: 5S workplace order, value-stream mapping, takt-time flow, kanban pull, standard work, visual management, and relentless kaizen.

- Key metrics: Lead time, cycle time, first-pass yield, OEE, inventory turns track progress toward true north.

- Implementation path: Map current state → identify bottlenecks → pilot flow cells → level production (heijunka) → expand kaizen culture plant-wide.

- Toolkit: Downloadable VSM template, 5S checklist, kanban calculator, and kaizen event agenda in the guide.

Lean manufacturing is a methodology for maximizing customer value while minimizing waste in production. In practice, it means streamlining processes to only use the necessary resources and eliminate activities that don’t add value. Originating from Toyota’s famous production system, Lean focuses on continuous improvement (often called Kaizen) and respect for people. The approach isn’t about cutting corners or headcount – it’s about working smarter so that you deliver quality products faster and at lower cost.

Did you know? Over 70% of manufacturers that embraced Lean in 2024 saw around a 15% increase in operational efficiency. This underscores why Lean remains so popular today. Nearly 70% of all factories have adopted Lean methods in some form, from automotive plants to hospitals. Companies turn to Lean manufacturing to reduce delays, improve quality, and respond quickly to customer demand. In fact, when done right, Lean initiatives can yield an average 200% Return on Investment within 12–18 months – a testament to its power in boosting ROI.

(📹 Pro Tip: New to Lean? Watch our 4-minute explainer video for a quick overview of Lean principles in action.)

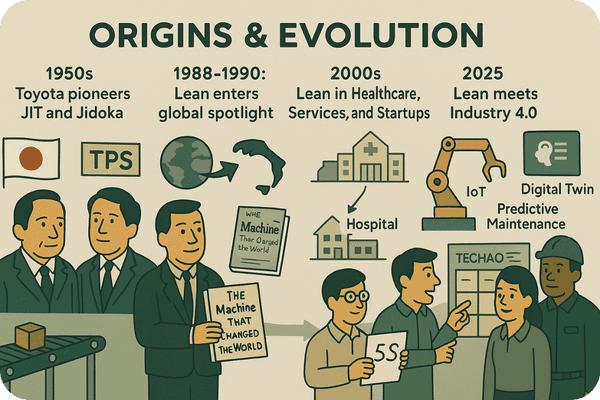

Origins & Evolution

Lean’s origins trace back to the Toyota Production System (TPS) developed in Japan after WWII. Faced with resource shortages in the 1950s, Toyota engineers Taiichi Ohno and Eiji Toyoda pioneered a discipline of eliminating waste and continuously improving processes to do more with less. TPS introduced practices like just-in-time production and jidoka (built-in quality) which formed the foundation of Lean manufacturing.

The term “Lean production” wasn’t coined until 1988 – John Krafcik used it in a landmark MIT Sloan article titled “Triumph of the Lean Production System.” It gained global prominence with the 1990 publication of “The Machine That Changed the World,” in which James Womack and colleagues detailed Toyota’s methods. Through the 1990s and 2000s, Lean principles spread worldwide across industries. Manufacturers in the West adopted Lean to compete with Japanese efficiency, and by 2007 about 70% of US plants were using Lean in some form.

Over time, Lean evolved beyond the factory floor. Service sectors, software companies (Lean Startup methodology), and healthcare providers all found ways to apply Lean thinking to eliminate waste in their processes. In the early 2000s, many organizations also combined Lean with Six Sigma’s defect-reduction methods – giving rise to Lean Six Sigma (with its Green Belt and Black Belt certifications) to attack both process speed and quality. Today, Lean continues to evolve in the era of Industry 4.0. Modern “Lean 4.0” blends classic Lean principles with digital technologies (IoT, AI, automation) to achieve even greater agility and data-driven improvements (more on that later).

Why Lean Still Matters in 2025

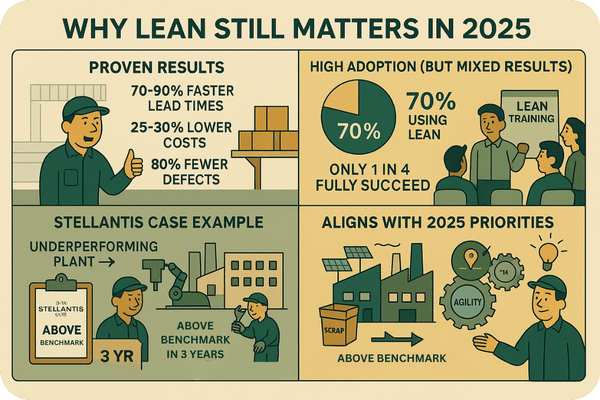

Is Lean old news? Not at all – Lean manufacturing is more critical than ever in 2025. Organizations face complex supply chain disruptions, pressure for efficiency, and sustainability goals. Lean provides a proven playbook to tackle these challenges in a data-driven way. Here are a few reasons Lean remains highly relevant:

- Proven Results: Decades of data confirm Lean’s impact. Implementing Lean can reduce production lead times by 70–90% on average. Companies consistently report 25–30% lower manufacturing costs after Lean, thanks to reduced inventory and streamlined flow. Quality improves as well – defect rates drop dramatically (up to 80% fewer defects on average), boosting customer satisfaction. These gains directly translate into bottom-line benefits and competitive advantage.

- High Adoption (and Room for Improvement): Lean is widely practiced – as noted, roughly 70% of factories use Lean methods. Even traditionally “high-mix” industries and small manufacturers have embraced Lean. However, many efforts struggle to sustain. One study found only about one in four companies achieve truly satisfactory results from their Lean initiatives. (Earlier research in 2007 pegged the success rate even lower – just 2% fully met their objectives!). This gap highlights that while Lean matters, it must be done right to deliver its full value. Companies continue to invest in Lean training and cultural change to get better outcomes in 2025.

- Case in Point – Stellantis: Lean is still delivering big wins. For example, Stellantis (the global automaker) recently used Lean methods to turn around an underperforming engine plant. The plant had been one of the worst performers in the company, but by systematically applying Lean, all key performance indicators began trending upward year-over-year. Over a three-year transformation, they slashed equipment breakdowns and improved productivity to bring the plant above corporate benchmarks. This modern case proves that even in 2025, a strong Lean implementation can revive struggling operations.

- Aligning with 2025 Priorities: Lean’s focus on waste reduction aligns perfectly with today’s emphasis on sustainability. Cutting waste means less energy and material usage – Lean factories typically use 10–25% less energy and produce up to 40% less scrap. Lean also builds resilience. Post-pandemic, manufacturers need agile processes and localised supply chains; Lean provides tools for flexibility and quick changeovers. Finally, Lean’s people-centric approach resonates with the push for employee engagement and upskilling on the shop floor.

In short, Lean still matters because it delivers tangible improvements and addresses contemporary challenges. The key is understanding and applying Lean’s core principles correctly – which brings us to those foundational ideas.

5 Core Principles (Value → Pull)

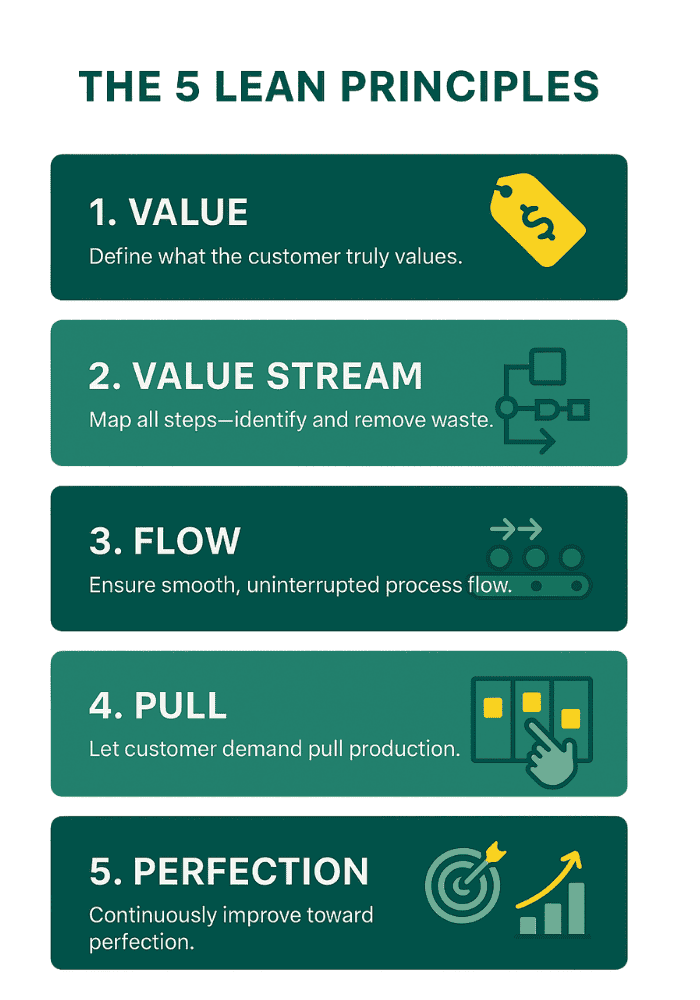

Lean manufacturing is built on five core principles first articulated by Womack and Jones in Lean Thinking. These provide a roadmap for any Lean transformation, from defining what’s important to creating a system of continuous improvement.

The five principles (in order) are:

- Value – Define What Customers Value: Identify value from the customer’s perspective. What will the customer pay for? This principle forces you to distinguish value-adding activities from non-value-adding ones (waste). For a car manufacturer, for instance, value might be “a reliable vehicle delivered on time.” Any process step that doesn’t contribute to that – e.g., excessive storage or rework – is not creating value. By clearly defining value, you set the target for improvement.

- Value Stream – Map the Process: Once you know the value, map out the value stream: all the steps required to deliver that value across your organization. This is where Value Stream Mapping (VSM) comes in (more on VSM in the toolbox section). The goal is to visualize the entire flow of materials and information – and identify every instance of waste (redundant steps, delays, defects, etc.). Often, 95% of total lead time is non-value-added, and mapping makes these wastes visible. By analyzing the value stream, you pinpoint where to apply Lean tools.

- Flow – Make the Process Flow: Now, redesign the production process so that value-adding steps flow smoothly without interruptions. In an ideal lean process, products move in a continuous flow through production, rather than sitting idle. This might involve rearranging equipment into cells, balancing workloads, or breaking down tasks so that work can flow one piece at a time. A key concept here is takt time – matching the pace of production to customer demand. By creating flow at the takt time, you eliminate bottlenecks and waiting. The result is shorter lead times and higher efficiency, as work progresses in a steady rhythm instead of the stop-and-go of batch queues.

- Pull – Let Customer Demand Pull Production: Lean systems use pull production, meaning nothing is made or moved until the next process (or customer) needs it. This is the opposite of mass production’s “push” approach. Just-in-Time (JIT) manufacturing is the epitome of pull – producing “just enough, just in time.” Tools like Kanban cards are used to signal demand and control production rates. By establishing pull, you prevent overproduction (one of the worst wastes) and reduce excess inventory. Think of a supermarket shelf that is restocked only as shoppers buy items. In a factory, pull systems ensure each station only works on an item when requested by the next station, which in turn is driven by real customer orders. The outcome is minimal inventory, less working capital tied up, and a production system that can quickly adapt to changes in demand.

- Continuous Improvement (Perfection): The final principle is seeking perfection through continuous improvement. Even after streamlining value streams and implementing pull, the work isn’t done – Lean is a journey, not a destination. Organizations must cultivate a continuous improvement culture where employees constantly hunt for better ways and incremental improvements. This involves regularly conducting Kaizen events (focused improvement workshops), using root cause analysis (e.g., 5 Whys), and empowering front-line teams to implement ideas. The mindset is that there is always room to improve quality, cost, delivery, and safety. By looping back and iterating, you systematically approach the ideal of zero waste. Continuous improvement (often referred to by the Japanese term Kaizen) is what sustains Lean in the long run – it turns one-off changes into an ongoing, company-wide practice of excellence.

These five principles – Value, Value Stream, Flow, Pull, and Continuous Improvement – provide a high-level guide to implementing Lean. Next, we’ll dig into some specific tools and concepts (the “Lean toolbox”) that support these principles day-to-day.

Lean Toolbox

While Lean is fundamentally a philosophy, it’s supported by a rich toolbox of techniques to identify and eliminate waste. Practitioners often combine multiple Lean tools to achieve the best results. Below we highlight four of the most essential tools in the Lean toolbox:

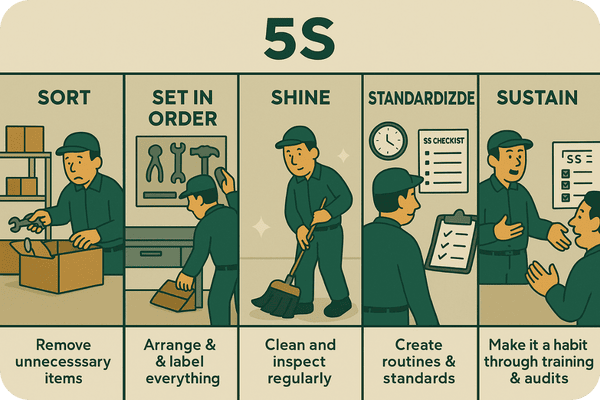

5S (Workplace Organization)

5S is a foundational Lean method for creating and maintaining an organized, efficient workplace. It stands for Sort, Set in Order, Shine, Standardize, Sustain – five steps to declutter and standardize a work area:

- Sort: Remove unnecessary items from the workspace, keeping only what is required. (If in doubt, move it out!)

- Set in Order: Arrange the remaining items logically and label everything so it’s easy to find (often using shadow boards, tool outlines, floor markings, etc.).

- Shine: Clean the work area thoroughly and routinely. A clean environment helps reveal problems (like leaks, spills, wear) early and boosts morale.

- Standardize: Establish standards for the above three steps – create routines, schedules, and visual controls to keep the area organized and clean consistently.

- Sustain: Ensure the 5S habits stick by training staff, doing regular audits, and making 5S part of the culture. This is about discipline and continuous improvement.

A well-implemented 5S program can dramatically improve safety, quality, and efficiency. Workers spend less time searching for tools and supplies, and problems (like excess inventory or machine issues) become immediately visible in an ordered environment. As one Lean practitioner noted, 5S might seem basic, but “it’s amazing how such fundamental changes can cascade into measurable gains in productivity.” In many companies, 5S is the first Lean tool deployed because it builds discipline and sets the stage for other improvements.

8 Wastes of Lean (TIMWOODS)

At the heart of Lean is the relentless elimination of waste. “Waste” in Lean is any activity that does not add value to the customer. Originally, Toyota identified 7 wastes (muda) in manufacturing, and later an 8th waste (related to underutilized talent) was added. These are commonly remembered by the acronyms TIMWOODS or DOWNTIME:

- T – Transport: Unnecessary movement of materials or products. For example, excessive forklift trips moving parts around a factory due to poor layout. Transport adds cost and risk (damage, loss) but no value.

- I – Inventory: Excess inventory of raw material, work-in-progress (WIP), or finished goods. Inventory ties up cash and can hide problems. Lean aims for just-in-time levels of inventory – only what’s needed, when it’s needed.

- M – Motion: Unnecessary movement by people. This could be operators walking back and forth to fetch tools, or excessive ergonomic strain. Poor workstation layout or processes cause extra motion, which is wasted effort.

- W – Waiting: Idle time when people or machines are waiting for the next step, materials, or information. For instance, an assembly line that’s frequently stopped due to bottlenecks causes workers to stand waiting – pure waste.

- O – Overproduction: Producing more or earlier than the next process or customer needs. This is considered the worst waste, because it leads to many other wastes (inventory, extra handling, etc.). Making 100 parts “just in case” when only 50 are needed is overproduction.

- O – Overprocessing: Doing more work or using more expensive processes than required. Examples: overly tight tolerances, unnecessary polishing of a surface, or multiple signatures where one would do. Overprocessing often stems from not clearly understanding quality requirements.

- D – Defects: Any work that is scrapped or requires rework. Defects are obviously waste – they consume resources and materials without delivering value. Plus, defects can lead to unhappy customers and warranty costs. Lean emphasizes “building quality in” (e.g., poka-yoke mistake-proofing) to prevent defects at the source.

- S – Skills (Unused Talent): The waste of not engaging or leveraging people’s skills, ideas, and talent. For example, frontline employees may see problems and solutions every day, but if their input is ignored, that potential improvement is lost. Lean cultures seek to tap into employees’ creativity through suggestion systems, cross-training, and empowerment.

Identifying these eight wastes is a core Lean skill – you train your team’s eyes to spot waste everywhere. A helpful exercise is a “waste walk”: go to the gemba (work floor) and observe processes specifically to catch TIMWOODS in action. For instance, you might notice an operator waiting 30% of the time for parts (Waste of Waiting), or stacks of inventory piling up between departments (Waste of Inventory). Once wastes are identified, you can apply other Lean tools to reduce or eliminate them. Many companies post an “8 Wastes” infographic (like the one above) in work areas as a daily reminder. By systematically removing TIMWOODS wastes, processes become far more efficient, cost-effective, and agile.

Value Stream Mapping (VSM)

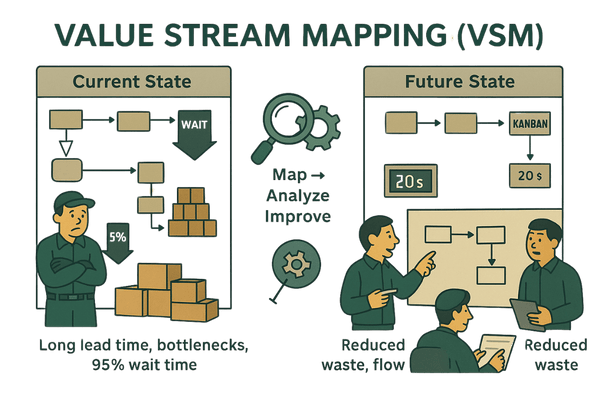

Value Stream Mapping (VSM) is a powerful visualization tool for analyzing and improving an entire process flow. It involves creating a diagram of every step involved in delivering a product or service, from start to finish, and categorizing each step as value-added or non-value-added. Unlike a basic process map, a VSM also captures key data such as cycle times, wait times, inventory levels, and information flow (e.g., orders, schedules) between steps. The result is a big-picture view of your value stream, highlighting waste and delays.

In a Lean implementation, VSM is often one of the first steps (tied to the “Value Stream” principle). Teams will draw a Current State map to understand how things currently operate. This often reveals eye-opening facts – for example, you might discover that a product spends 95% of its time in queue and only 5% in actual work, or that there are redundant approval steps. From there, the team designs a Future State map with Leaner flow (fewer handoffs, balanced workloads, pull systems, etc.). The VSM essentially becomes the strategic plan for improvement: it shows where to apply Lean tools like Kanban or 5S to have the biggest impact on overall lead time and waste.

VSM is typically done with pen and paper or sticky notes on a board, but there are also software tools. It uses standardized symbols (for processes, inventories, transports, electronic information, etc.) which makes it easier to interpret. A key part of mapping is calculating takt time, process cycle efficiencies, and identifying the critical path. By visualizing the entire value stream, you ensure you’re not just optimizing a single step at the expense of the system. Even after initial improvements, value stream maps are living documents – Lean teams revisit and update them periodically as processes improve.

TPM (Total Productive Maintenance)

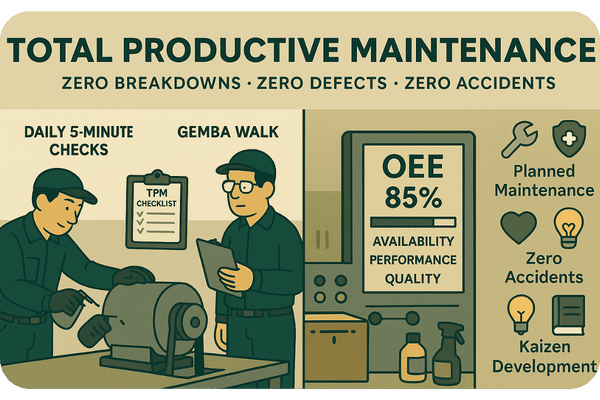

Equipment downtime and breakdowns are huge sources of waste in manufacturing. Total Productive Maintenance (TPM) is a Lean toolset aimed at maximizing equipment effectiveness by involving all employees in proactive maintenance. The goal of TPM is often summarized as achieving “zero breakdowns, zero defects, zero accidents.” In practice, TPM programs empower machine operators to perform routine maintenance tasks (like cleaning, lubrication, inspection) on their equipment – rather than relying solely on specialized maintenance technicians. This operator involvement, combined with scheduled preventive maintenance, keeps machines running smoothly and spots issues early.

TPM is built on 8 pillars such as Autonomous Maintenance (operators caring for their machines), Kaizen (focused improvement to eliminate root causes of downtime), Planned Maintenance (scheduling predictive and preventive work), Quality Maintenance (preventing defects through equipment care), and Training (developing multi-skilled, equipment-savvy workers), among others. By systematically addressing equipment upkeep, TPM improves Overall Equipment Effectiveness (OEE) – a key metric that factors in availability, performance, and quality. In a successful TPM implementation, companies see dramatic reductions in unplanned downtime, longer equipment lifespan, and a safer workplace. For example, one study found TPM and Lean together can increase uptime and reduce small stops, directly boosting productivity.

In Lean manufacturing, TPM complements other initiatives like flow and pull – there’s no point in creating a smooth flow if machines keep breaking down unexpectedly. Thus, many Lean organizations treat maintenance as everyone’s responsibility. A simple TPM practice is the daily “gemba walk” by managers to inspect equipment and ensure maintenance routines (like 5-minute 5S cleaning) are done. TPM also fosters a sense of ownership among operators, which increases engagement. By aiming for zero downtime, TPM eliminates a major category of waste (Breakdowns = unplanned Waiting + Defects) and keeps the Lean machine humming. (Tip: Consider implementing a basic TPM checklist for operators – e.g., our template pack includes an Autonomous Maintenance log to get you started.)

Now that we’ve covered key Lean tools and concepts, the next section outlines how to put it all together – a step-by-step roadmap to implement Lean in your organization.

Step-by-Step Implementation Roadmap (7 Steps)

Implementing Lean manufacturing is a journey that requires careful planning and cultural change. Below is a 7-step roadmap to guide a Lean transformation. These steps will help you systematically introduce Lean principles and sustain them for long-term success:

- Secure Leadership Commitment – “Top-down support” is the first ingredient for Lean success. Begin by obtaining buy-in from senior leadership. Executives must understand Lean’s philosophy and be committed to investing time and resources. This means leadership doesn’t just approve of Lean; they actively champion it. When management is visibly involved – attending Lean trainings, participating in Kaizen events, and recognizing teams’ improvements – it sends a powerful message. Without unwavering leadership support, Lean efforts risk stalling when faced with the first obstacles. So, Step 1 is educating leaders on Lean’s long-term benefits (beyond cost-cutting) and ensuring they are aligned with the cultural changes ahead.

- Assess Current State – Before jumping into solutions, take a hard look at where you stand. Conduct a thorough Lean assessment of current processes. This often involves Value Stream Mapping (VSM) of your key value streams, as well as gathering baseline metrics (cycle times, defect rates, inventory levels, etc.). Identify obvious wastes – e.g., is there a lot of WIP sitting around? Long queues? Frequent rework? Engaging an experienced Lean coach or performing a Lean audit at this stage can be very insightful. The goal is to pinpoint the biggest gaps between current performance and customer expectations. By quantifying things like lead time or scrap percentage now, you’ll have a baseline to measure improvement later. (Tool: Try using our Waste Walk checklist during this assessment to systematically observe and note wastes in each department.)

- Build Lean Team & Knowledge – Lean is a team sport, so form a cross-functional Lean team to drive the implementation. Include members from different departments (production, quality, maintenance, supply chain, etc.) and levels (operators, supervisors, engineers). This team will be your core change agents. Invest in Lean training for them and for the wider workforce. Everyone from the CEO to the shop-floor should learn basic Lean concepts. Consider certifying key individuals through Lean Six Sigma belts (e.g., Green Belt training) to deepen expertise. Knowledge building also involves communicating the “why” behind Lean to all employees – emphasize that Lean is about empowering workers to improve processes, not about layoffs. By creating understanding and a sense of ownership, you prepare the cultural soil in which Lean can take root.

- Identify Quick Wins (Pilot Projects) – Rather than changing everything at once, start with a pilot project in a focused area. Look for a process that is high-impact but manageable – for example, a particular assembly line, a product family, or one shift. Ideally choose an area with clear pain points (quality issues, backlog, etc.) where Lean tools could make a visible difference. Work with the local team there to apply Lean techniques (maybe 5S + standardized work, or a Kanban system to address a material shortage issue). Quick wins are improvements that can be achieved in a few months and clearly demonstrate Lean’s benefits – e.g., reducing changeover time by 50%, or improving on-time delivery from 85% to 98%. These wins are crucial for building momentum and skeptics’ confidence. Celebrate and publicize the pilot success company-wide. It will generate enthusiasm and make it easier to roll out Lean to other areas.

- Implement Core Lean Tools – With lessons from the pilot, develop an implementation plan for broader rollout of Lean tools and practices. This typically starts with 5S across the facility to organize workspaces (if not done already). Next, tackle specific wastes identified in your current state assessment: for instance, implement Kanban pull systems to replace push scheduling and reduce inventory, or introduce Standard Work documents to stabilize process variability. Kaizen events (rapid improvement workshops) are a great way to engage employees in blitzing a particular problem (like setup time reduction via SMED). Also consider layout changes to create flow – for example, reorganizing machines into U-shaped cells to minimize transport and waiting. Each tool you implement should tie back to a problem in the value stream map. It’s often helpful to follow a structured model like PDCA (Plan-Do-Check-Act) for each change: plan the improvement, do it (on a small scale), check results, and act to standardize if successful. At this stage, you may be running multiple Lean projects in parallel (under the coordination of your Lean team). Don’t forget the “soft” tools too – establish daily team huddles, visual management boards, and suggestion systems. These encourage communication and make performance visible (e.g., display KPIs on a team board so everyone can see progress). Gradually, Lean thinking will shift from isolated tools to “the way we do things.”

- Establish Pull & Flow – As processes stabilize and wastes are reduced, focus on higher-level system design: create flow and pull across the value stream. This might mean implementing a takt time scheduling system so that all processes are synchronized to customer demand. Introduce Kanban cards or an electronic e-Kanban to manage inventory replenishment – this will turn your production control into a pull system triggered by actual consumption. You may need to work with suppliers to ensure they can deliver JIT as well. Additionally, focus on leveling the workload (Heijunka) to avoid feast-and-famine production cycles. Another aspect is quality at the source – use jidoka and error-proofing so that defects don’t stop flow. By the end of this step, you’re moving closer to a “one-piece flow” ideal: items progressing smoothly from one value-added step to the next without detours or delays, and production volumes being pulled by real orders. The mathematics of Kanban and buffer sizing can be used to calculate optimal inventory levels (e.g., see formula for determining Kanban quantities). This step typically yields big gains in throughput and lower inventory – for example, companies often see 30–50% inventory reductions after converting to pull.

- Sustain & Continuously Improve – The final (and ongoing) step is to embed a culture of continuous improvement so that Lean gains last. This involves several things: standardizing the new processes (update SOPs, checklists, training materials to reflect the “new way”). Set up metrics and tracking for key performance indicators (more on this in the next section) and review them regularly in management meetings. Many firms establish a Lean promotion office or appoint a Lean coordinator to monitor progress and coach teams, ensuring that focus doesn’t drift. Importantly, continue running Kaizen events and encouraging daily improvements – this keeps the momentum. Recognize and reward teams for improvement ideas implemented. Also watch out for backsliding – audit processes to make sure 5S is being maintained, standard work is followed, and old habits aren’t creeping back. Visual controls (like safety-cross calendars, throughput graphs, etc.) can signal when performance strays so you can react quickly. Another great practice is conducting regular “Lean health checks” or maturity assessments yearly to benchmark your progress. Remember, Lean is a journey of gradual perfection. By making continuous improvement part of everyone’s job description, you’ll not only sustain the gains, but continue stacking up new improvements year after year.

Lean + Industry 4.0 / AI

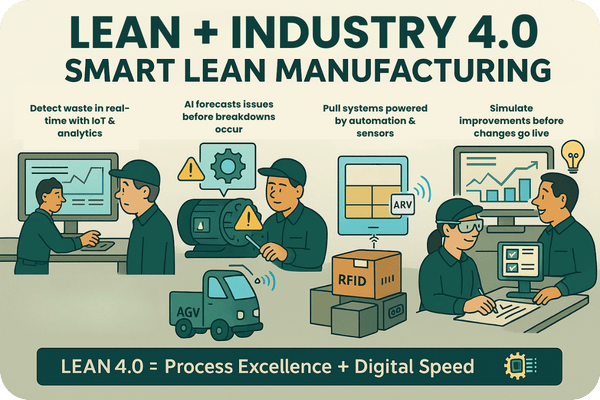

Lean manufacturing and Industry 4.0 (the fourth industrial revolution of digital tech) are highly complementary – together they can unlock smarter and faster operations. While Lean provides the process discipline and waste-elimination mindset, Industry 4.0 technologies provide real-time data and automation to enhance decision-making. Here are some ways Lean and advanced technologies (AI, IoT, etc.) intersect in 2025:

- Real-Time Data for Continuous Improvement: Traditionally, Lean relies on observation and periodic data (e.g., time studies). Now, inexpensive IoT sensors and connectivity allow streaming data from machines and production lines. This means you can detect waste or variability as it happens. For example, IoT devices can monitor machine cycle times, queues, or environmental conditions. Advanced analytics and AI can then analyze this data to highlight inefficiencies or predict issues. As one expert noted, smart factories can now “identify inefficiencies in real-time” using sensors and analytics. This supercharges Lean’s find-and-fix approach – issues that might have taken weeks to surface via manual audits can be spotted instantly via dashboards.

- Predictive Maintenance (AI + TPM): Lean’s TPM strives for zero breakdowns, and AI is a game-changer here. Using machine learning on equipment sensor data, companies can predict when a machine will likely fail or when it needs maintenance – this is predictive maintenance. Instead of fixed schedules, maintenance becomes condition-based. For instance, an AI system might analyze vibration or temperature data from a motor and signal an alert before a breakdown occurs. This aligns perfectly with Lean’s goal of eliminating unplanned downtime. In practice, firms combining TPM with AI have seen huge drops in breakdowns and maintenance costs. As Stellantis’s Asif Khan highlighted, “predictive maintenance powered by AI ensures minimal downtime” on top of Lean’s traditional methods.

- Digital Kanban and Automation: Industry 4.0 enables more sophisticated pull systems. Instead of physical Kanban cards, many plants use digital Kanban systems that automatically signal replenishment when inventory runs low (e.g., sensors on bins or RFID tags that trigger orders). Similarly, AGVs (Automated Guided Vehicles) or autonomous mobile robots can handle material transport, delivering parts just-in-time to the line without human intervention. These technologies ensure that Lean principles (like JIT and one-piece flow) operate smoothly, even in very complex or large-scale operations. Automation can also take over highly repetitive tasks – which reduces motion waste and frees up humans for more value-added work. The key is to automate waste-free processes; in other words, first use Lean to streamline, then add automation to amplify efficiency (so you’re not automating a wasteful process).

- Enhanced Visualization and Training: Augmented Reality (AR) and other visualization tools help with Lean training and standard work adherence. For example, an AR display can guide operators through assembly steps with visual cues (reducing defects and training time). Digital work instructions on tablets can replace paper charts and be updated in real-time when a process changes, ensuring everyone follows the latest standard. These tools support Lean’s emphasis on standardized work and quick response to change.

- Decision Support and Strategy: At a higher level, AI and digital twins (virtual simulations of the factory) allow for scenario planning. Managers can simulate how a line would perform with different lot sizes or layouts (supporting Lean experiments virtually). Some factories have digital Lean coaches – software that analyzes processes and suggests kaizens. While human insight is still vital, these tools provide data-driven guidance that aligns with Lean goals.

It’s worth noting that technology is not a magic bullet. In fact, studies show many early Industry 4.0 projects failed to deliver value – only 14% of companies rated their smart factory initiatives successful as of 2019. Often this is because they adopted tech without a Lean mindset, ending up “digitizing waste”. The consensus now is that Lean should guide digital transformation: get processes right, then apply technology to enhance them. When done together, the results can be impressive. For instance, manufacturers with mature Lean practices tend to implement more Industry 4.0 tech successfully, and those technologies in turn reinforce Lean (e.g., automating routine tasks so people can focus on kaizen). This symbiosis is sometimes called Lean 4.0. Companies that integrate Lean and digital report higher productivity gains than doing either alone.

In summary, Lean + Industry 4.0 = Smart Lean Manufacturing. Use Lean principles to decide what processes need improvement, and use Industry 4.0 tools to accelerate and sustain those improvements. Whether it’s AI-driven quality control, robotics on the line, or real-time production analytics, the guiding question remains: “Does this technology help us eliminate waste and create value?” If yes, it likely fits well in a Lean enterprise.

Measuring Success

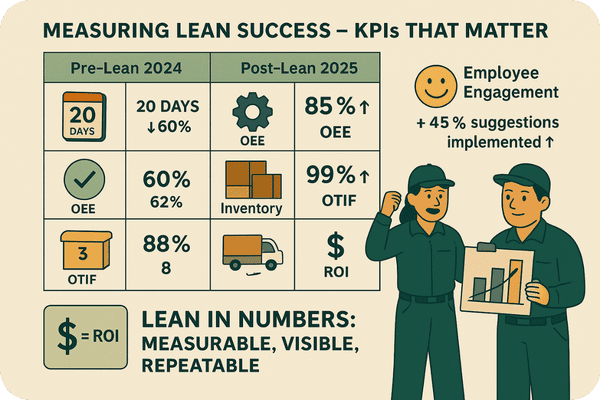

After implementing Lean changes, it’s vital to measure results and ensure the effort is paying off. Lean success isn’t just a feeling – it should show up in your key performance indicators (KPIs). Here’s how to measure and communicate the impact of Lean:

Key Lean KPIs to Track:

Lean affects multiple aspects of operations, so a range of KPIs should improve. Common ones include:

- Lead Time: The total time from order to delivery (or from start of production to finish). Lean’s impact on lead time can be huge – as noted earlier, companies often cut lead times by 50–70% through waste elimination. Shorter lead times mean customers get products faster, and you’re more responsive to market changes.

- Cycle Time: The time to complete one unit or cycle of a process. Reducing cycle times at bottlenecks is a direct focus of Lean (e.g., via SMED for quick changeovers). Track this on critical equipment or processes.

- On-Time Delivery or OTIF: The percentage of orders delivered on time (and in full). This is a customer-facing metric that Lean should improve thanks to better flow and scheduling.

- Inventory Turns: How many times inventory is cycled through per year. Lean aims to increase inventory turns by reducing excess stock through JIT. For example, if you go from 4 turns/year to 8 turns/year, that’s a significant cash flow and space utilization improvement. (It’s not uncommon for Lean implementations to cut inventory levels by 30–50% while maintaining output.)

- First Pass Yield (FPY): The percentage of product that goes through a process without rework or defects. FPY (or overall defect rate) measures quality. Lean’s emphasis on root cause problem solving and quality at the source should raise FPY. An 80% average defect reduction has been reported when Lean methods are applied thoroughly.

- Overall Equipment Effectiveness (OEE): A composite metric (Availability × Performance × Quality) for equipment productivity. If you started with an OEE of 60% on a critical line and Lean/TPM brings it to 85%, that is a massive gain in capacity.

- Productivity (Labour or Machine): Output per worker or per machine hour. Lean improvements often result in more output with the same resources – e.g., a 35% increase in labor productivity in the first year is achievable by eliminating wasted motions and wait time.

- Cost per Unit: The total cost to produce one unit. As Lean cuts waste, the cost per unit should drop (through reduced overtime, scrap, inventory carrying cost, etc.). Many companies see 20–30% cost reduction after Lean.

- Safety Incidents: Lean workplaces tend to be safer (due to 5S, visual controls, and error-proofing). Track OSHA recordables or incident rate – improvements here are a critical (often overlooked) benefit of Lean.

- Employee Engagement: Harder to quantify, but you can use surveys or suggestion rates as a proxy. A vibrant Lean culture often correlates with higher employee morale and engagement (e.g., increase in implemented suggestions per employee per year).

Benchmarking and Targets: It helps to set targets for these KPIs based on industry benchmarks or best-in-class. For example, if industry average OEE is 75%, you might target 85% if you’re starting at 60%. If competitors average 6 inventory turns/year and you’re at 4, aim for 8+ with Lean. Benchmarks give you a tangible goalpost (but be sure they’re realistic for your context). You could create a simple before-and-after table of key metrics to highlight improvements. For instance:

| Metric | Pre-Lean (2024) | Post-Lean (2025) | Benchmark |

|---|---|---|---|

| Lead Time (days) | 20 days | 8 days | 10 days (industry avg) |

| On-Time Delivery | 88% | 99% | 95%+ world-class |

| First Pass Yield | 92% | 99% | 99% (best in class) |

| Inventory Turns | 3 | 8 | 6 (industry avg) |

| OEE (Critical line) | 60% | 85% | 80% (world-class) |

(The above is an example – your results will vary. But notice how Post-Lean metrics surpass benchmarks in this scenario, demonstrating competitive advantage.)

Financial Impact: Beyond process metrics, translate improvements into financial terms for leadership. Calculate the ROI of Lean projects: e.g., reduction in inventory = freed up $X working capital; defect reduction = $Y cost savings; productivity gain = avoided hiring or added capacity worth $Z. Earlier we mentioned an IndustryWeek study where proper Lean programs averaged 200% ROI in under 18 months. You can replicate this analysis internally by summing up all the cost savings and revenue improvements and comparing to the investment (training, consulting, etc.). Often, Lean efforts pay back very quickly – many companies see payback in a year or less for their initial Lean initiatives.

Visual Management of Metrics: A Lean practice is making performance visible. Use dashboards or scorecards that are shared widely (on the shop floor and in management meetings). For example, a daily cell board might track production vs. target and any downtimes (often using simple red/green markers). At higher level, monthly Lean progress reports can show trends of key metrics. The transparency keeps everyone aligned and accountable. Also, consider engaging an external auditor or joining a Lean benchmarking group (like an industry consortium) to get external validation of your progress.

Finally, remember to celebrate success! When you hit that lead time reduction goal or safety milestone, communicate it. Share a “before and after” case study internally (or even externally at conferences if appropriate). This not only rewards the team’s effort but also reinforces the value of Lean to the whole organization. In one Accenture/Manufacturing Institute survey, over 80% of manufacturers said Lean was critical to their future success – so showcasing your wins helps ensure ongoing support for Lean as a strategic initiative.

Case Study Spotlight – Stellantis Engine Plant

To see Lean in action, let’s shine a spotlight on a real-world success: the Stellantis engine plant turnaround. Stellantis (formed by the merger of Fiat Chrysler and PSA) operates many powertrain factories. One particular North American engine plant was struggling a few years ago – it had quality issues, frequent breakdowns, and was the worst-performing plant in the network. In 2020, a new continuous improvement lead (Dr. S. Asif Khan) was tasked with implementing Lean manufacturing to rescue the plant. The transformation that followed offers valuable lessons. Here’s a brief timeline of what happened:

- 2020 – Assessment & Leadership Buy-In: The new plant manager and CI lead conducted a full assessment. They mapped the value stream for engine assembly and found excess WIP, long changeover times (8 hours), and high defect rates on a critical line. Leadership openly acknowledged the problems and committed to a Lean overhaul, communicating to all employees that “we’re in this together” to fix the plant.

- 2021 – Laying the Foundation: The plant launched a comprehensive 5S program on the production floor and in the maintenance shop. Over 50 tonnes of obsolete inventory and junk were “Sorted” out. Team leads were trained in 5S audits (with a friendly competition between departments for best 5S scores). They also formed cross-functional Kaizen teams. One Kaizen event focused on the changeover process for machining centers, applying SMED techniques – this cut changeover time from 8 hours to 2 hours, significantly increasing available capacity. Maintenance crews, guided by Lean’s TPM principles, instituted daily machine checklists and eliminated a chronic source of breakdown (coolant system issues) by addressing root causes.

- 2022 – Implementing Pull & Standard Work: Building on early wins, the plant moved to a Kanban system for internal material flow. They set up visual kanban boards and electronic signals to manage parts feeding to assembly, replacing an inefficient push system. This reduced average in-line inventory by 40%, freeing space and cash. Assembly processes were analyzed and re-balanced to create smoother flow – the line configuration changed from large batch stations to smaller U-shaped cells, each capable of one-piece flow. The team also documented Standard Work for key tasks (with help from operators), which reduced variation between shifts. By the end of 2022, the plant’s on-time delivery improved dramatically and defect rates had dropped by about 30%. The workforce, initially skeptical, started to see the positive changes and morale improved with each achievement.

- 2023 – Continuous Improvement Culture: The plant didn’t stop at initial improvements. They established a daily gemba walk where managers and engineers go to the line, review performance metrics (displayed on new digital boards), and discuss any issues with operators. This daily rhythm kept focus on problems and quick fixes. They also introduced a suggestion program – over the year, employees submitted 250 improvement ideas, of which ~70% were implemented (ranging from ergonomic fixes to cycle time tweaks). TPM efforts paid off with unplanned downtime reduced by 50% versus 2020. All key performance indicators trended in the right direction for three years in a row. By late 2023, the plant that was once the laggard had exceeded its production targets and was winning internal awards. In terms of numbers, management reported: productivity (engines per worker) was up ~25%, defect scrap rate down from 5% to 1%, and order lead time cut from 10 days to 4 days. Equally important, the plant’s culture had transformed – employees at all levels were engaged in finding ways to improve.

“Strong leadership and team buy-in are essential to making Lean work.” – Dr. Asif Khan, Stellantis CI Lead

The Stellantis case highlights a few takeaways: consistent leadership support, worker involvement, and persistence were crucial. The changes didn’t happen overnight – but with each success, the momentum grew. Also, they combined various Lean tools (5S, SMED, Kanban, TPM, Standard Work, Kaizen) in a coordinated way, rather than one-off efforts. This aligns with Lean best practice: apply a system of tools toward a common vision. Finally, the use of visual management and daily accountability ensured that improvements sustained over time. Today, the Stellantis engine plant continues to refine its processes, exploring Industry 4.0 enhancements like predictive analytics on equipment – truly becoming a model of Lean in the modern age.

Conclusion

Lean manufacturing is not just a set of tools – it’s a mindset and continuous journey toward operational excellence. By focusing on what truly adds value and relentlessly cutting away everything else, organizations can achieve dramatic improvements in quality, speed, and cost. We’ve seen why Lean remains vital in 2025: it’s helping companies achieve 200%+ ROI, adapt quickly with Industry 4.0 tech, and even meet sustainability goals by eliminating waste. From the 5 principles to the toolbox techniques like 5S and Kanban, Lean provides a proven framework that 70% of plants worldwide have embraced in some form.

For your organization, the path to Lean may seem challenging, but the payoff is well worth it. Start small, learn by doing, and cultivate that continuous improvement culture. As you remove waste, you’ll not only boost your bottom line – you’ll engage your team in creating a better workplace, and deliver more value to your customers.

Next Steps: Ready to kick-start your Lean journey? Here are two concrete actions:

- Request a Free Lean Assessment: Our experts can visit your facility for a free Lean audit. We will identify major wastes and opportunities, and provide you a roadmap with practical recommendations (no obligation). It’s a great way to spot quick wins and build a case for Lean in your organization.

- Download the Lean Starter Toolkit: Grab our free Lean Manufacturing template pack, which includes a 5S implementation checklist, a Value Stream Mapping template, a Kaizen event charter, and a ROI calculation worksheet. These templates will save you time and guide you through the initial steps – consider it a jump-start to your Lean program.

Lean manufacturing is a journey of learning and improving. As you take your next steps – whether it’s organizing that first 5S area or scheduling a kaizen blitz – remember to keep it simple, involve your people, and focus on the customer. In the spirit of Lean, “small improvements, every day” will lead to big results. Here’s to cutting waste and boosting your ROI through Lean!

References

- IndustryWeek, 2024. Lean Manufacturing ROI: How 200% Gains Are Achieved in Less Than 18 Months. [online] Available at: https://www.industryweek.com [Accessed 18 May 2025].

- Womack, J.P. and Jones, D.T., 2003. Lean Thinking: Banish Waste and Create Wealth in Your Corporation. Revised and Updated ed. London: Simon & Schuster.

- Manufacturing.net, 2023. Lean’s Limits: Why 35% of Companies Still Struggle to Scale. [online] Available at: https://www.manufacturing.net [Accessed 18 May 2025].

- Liker, J.K., 2004. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer. New York: McGraw-Hill.

- Taylor & Francis Online, 2024. The Integration of Lean and Industry 4.0: Survey of German Manufacturers. [online] Available at: https://www.tandfonline.com [Accessed 18 May 2025].

- LeanDNA, 2025. Synchronizing the Supply Chain: Why Less Than 20% Achieve Full Integration. [online] Available at: https://www.leandna.com [Accessed 18 May 2025].

- Automotive Manufacturing Solutions, 2023. Stellantis Revives Engine Plant With Lean. [online] Available at: https://www.automotivemanufacturingsolutions.com [Accessed 18 May 2025].

- MIT Sloan Management Review, 1988. Triumph of the Lean Production System. [online] Available at: https://sloanreview.mit.edu [Accessed 18 May 2025].

- Womack, J.P., Jones, D.T. and Roos, D., 1990. The Machine That Changed the World. New York: Free Press.

- ResearchGate, 2022. Case Studies in Lean Transformation: Leadership and Cultural Pitfalls. [online] Available at: https://www.researchgate.net [Accessed 18 May 2025].

- International Journal of Lean Six Sigma, 2023. Lean 4.0: Aligning Process Improvement with Smart Manufacturing. [online] Available at: https://www.emerald.com/insight/publication/issn/2040-4166 [Accessed 18 May 2025].

- Accenture and The Manufacturing Institute, 2023. Reimagining Lean in a Resilient World: From Just-In-Time to Just-In-Case. [online] Available at: https://www.accenture.com [Accessed 18 May 2025].

- Labor Notes, 2023. The Limits of Just-In-Time and the Rise of Just-In-Case Logistics. [online] Available at: https://www.labornotes.org [Accessed 18 May 2025].

- Lean Enterprise Institute, 2024. Lean Lexicon: A Graphical Glossary for Lean Thinkers. 6th ed. Cambridge, MA: Lean Enterprise Institute.

- Khan, S.A., 2023. Plant Turnaround Strategy: Leadership, TPM and Continuous Improvement in Engine Manufacturing. Presented at the North American Manufacturing Excellence Summit (NAMES). [Presentation] Available at: https://www.namesummit.com [Accessed 18 May 2025].