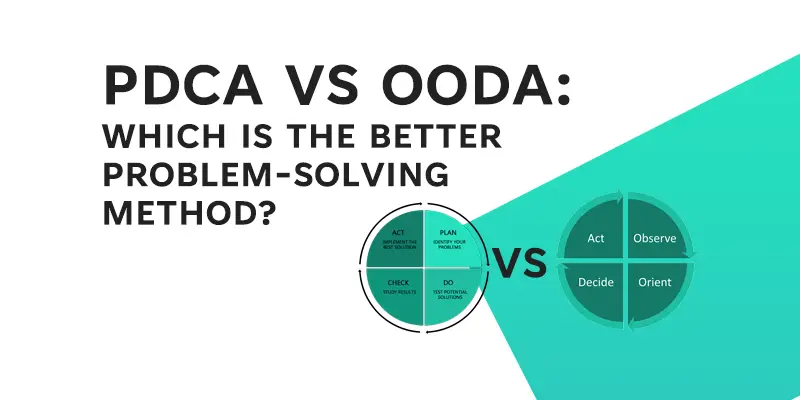

Choosing the right problem-solving framework is a pivotal decision that can significantly influence the efficiency and effectiveness of any organization. With a multitude of methodologies out there, PDCA (Plan-Do-Check-Act) and OODA (Observe-Orient-Decide-Act) stand out as tried-and-true approaches to tackling complex challenges.

While PDCA has its roots in quality control and continuous improvement, OODA originated in military strategy and has been adapted for rapid decision-making across various fields. This article aims to dissect both frameworks to help you discern which is better suited for your problem-solving needs. We’ll delve into the origins, key steps, and practical applications of each method, analyze their strengths and weaknesses, and even look at real-world case studies. By the end, you’ll be equipped to make an informed choice between PDCA and OODA.

Understanding PDCA

Origin of PDCA

The PDCA cycle, often referred to as the Deming Wheel or Shewhart Cycle, is a four-step model for continuous improvement and problem-solving. Conceived by Walter Shewhart, an American statistician, and later popularized by W. Edwards Deming, the cycle has its roots in quality control during the manufacturing processes of the mid-20th century. The framework has since transcended its initial context, becoming a universal model applied in various industries and sectors for quality management and improvement.

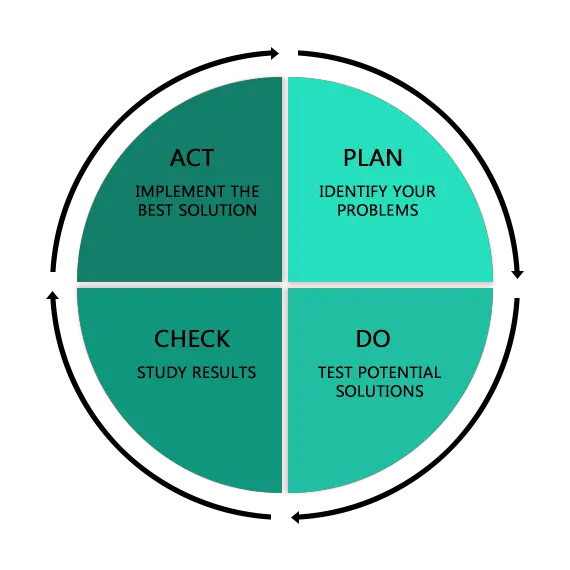

Four Steps Explained

- Plan: The first step involves identifying a problem or a potential improvement area and then planning a change. This phase typically encompasses setting objectives, determining the resources required, and devising the metrics that will gauge success or failure.

- Do: This step entails implementing the planned change on a small scale as a pilot test. It’s crucial to document all changes and data collected so that the information can be analyzed later.

- Check: Here, the data collected during the ‘Do’ phase is analyzed. The purpose is to evaluate whether the change led to improvement and met the objectives set during the ‘Plan’ phase.

- Act: In the final step, if the change is deemed successful, it is implemented on a broader scale. If not, the cycle begins anew, aiming to refine the plan with the insights gained.

Industries Where PDCA is Commonly Used

Given its origins in manufacturing, PDCA is most commonly used in this sector for quality control and process improvement. However, the versatility of the PDCA cycle has made it applicable in several other industries as well, including:

- Automotive

- Healthcare

- Software Development

- Education

- Public Sector

- FMCG (Fast-Moving Consumer Goods)

- Logistics and Warehousing

Strengths and Weaknesses

Strengths

- Simplicity: The PDCA cycle is straightforward, easy to understand, and implement.

- Flexibility: It can be applied to a wide array of problems and industries.

- Data-Driven: The methodology encourages data collection for informed decision-making.

- Continuous Improvement: Being cyclical, it fosters a culture of ongoing improvement.

Weaknesses

- Limited Scope: PDCA may not be ideal for solving complex, multifaceted problems.

- Resource Intensive: It often requires thorough planning and data collection, demanding more resources than some other rapid models.

- Repetitiveness: If not done carefully, the cycle can become an endless loop without resolution.

By understanding PDCA in depth, you can better evaluate its utility for your specific needs, especially when comparing it to other methodologies like OODA. This framework has its merits and limitations, making it crucial to understand when and where it can best be applied.

Understanding OODA

Origin of OODA

The OODA Loop, which stands for Observe, Orient, Decide, and Act, was developed by U.S. Air Force Colonel John Boyd. Originally, the framework was used for combat operations processes to make faster and more effective decisions in fluid, high-stakes environments. Boyd’s concept has transcended its military roots and is now utilized in various settings, including business and crisis management, to aid in rapid decision-making and adaptive strategies.

Four Steps Explained

- Observe: This is the initial phase where you collect raw data from your environment. It involves actively scanning for information that could impact your decisions. This could be market trends, customer feedback, or any other form of actionable data.

- Orient: In this phase, you process the information gathered. You use your existing knowledge, cultural background, and prior experiences to interpret the raw data. This is the stage where contextual analysis occurs.

- Decide: Based on the orientation phase, you formulate a set of possible actions or decisions. You weigh the pros and cons and select the best course of action for your specific situation.

- Act: Finally, you implement the decision made. Unlike PDCA, where the ‘Do’ phase often involves a small-scale test, OODA’s ‘Act’ is usually swift and large-scale, aiming for immediate results.

Industries Where OODA is Commonly Applied

While OODA originated in the military, its principles of rapid, adaptive decision-making have been adopted in several other sectors, such as:

- Emergency Services and Crisis Management

- Financial Trading

- Healthcare

- Cybersecurity

- Competitive Sports

- Strategic Business Management

Strengths and Weaknesses

Strengths

- Speed: OODA is designed for rapid decision-making, making it suitable for volatile environments.

- Adaptability: The framework is inherently adaptable, allowing for quick adjustments in strategy.

- Situation Awareness: The ‘Observe’ and ‘Orient’ phases ensure a strong awareness of environmental variables.

- Immediate Action: Allows for direct, often large-scale, action based on situational awareness.

Weaknesses

- Risk of Hasty Decisions: The speed of the cycle can sometimes lead to hastily made, less-than-optimal decisions.

- Context-Specific: OODA may not be as effective for problems that require a detailed, long-term planning approach.

- Resource Intensive: Despite its speed, effective observation and orientation can be resource-intensive.

- May Lack Depth: Due to its emphasis on speed, there may be insufficient time for in-depth analysis or testing.

Understanding the intricacies of the OODA Loop will empower you to decide when it is the most appropriate methodology to employ. Like PDCA, OODA has its own set of pros and cons that make it suitable for certain scenarios and not for others.

Key Differences Between PDCA and OODA

Understanding the distinctions between PDCA and OODA is essential for choosing the right framework for your needs. Both methodologies have their unique strengths and weaknesses, but they differ in several key aspects, from speed to suitability for various industries. Let’s dive into these differences.

Speed of Implementation

- PDCA: Generally, PDCA is more deliberate and takes a longer time for implementation. This is mainly because of its emphasis on planning and checking, which includes data collection, analysis, and pilot testing.

- OODA: Designed for rapid decision-making, the OODA Loop focuses on quick, large-scale implementation, often bypassing smaller tests or in-depth analysis for immediate action.

Flexibility and Adaptability

- PDCA: While PDCA is flexible and can be applied to a wide range of industries, its structured approach means that changes during implementation are more difficult and time-consuming.

- OODA: The OODA Loop is inherently adaptive, allowing for quick pivots and strategy shifts. It’s designed to deal with rapidly changing, fluid environments.

Complexity of Problems Addressed

- PDCA: This methodology is generally better suited for problems that can be defined clearly and that require a structured approach to solution-building. However, it may struggle with extremely complex, adaptive challenges.

- OODA: OODA excels in high-stakes, complex situations where decisions need to be made quickly and adaptively. It’s particularly effective when the problem parameters are constantly changing.

Required Resources

- PDCA: PDCA often requires more resources for planning, data collection, and analysis. The iterative nature of the cycle also implies that multiple rounds may be needed, each consuming additional resources.

- OODA: Although speedy, OODA still requires significant resources for the observation and orientation phases to be effective. It may require specialized knowledge or technologies to gather and process real-time data.

Suitability for Various Industries

- PDCA: Originating from manufacturing and quality control, PDCA is commonly used in sectors that value process optimization and continuous improvement, such as healthcare, education, and logistics.

- OODA: Initially designed for military applications, OODA has been adapted for use in industries that require rapid response and adaptability, such as emergency services, financial trading, and cybersecurity.

In sum, PDCA and OODA offer contrasting approaches to problem-solving and decision-making. PDCA is a methodical, data-driven framework suitable for well-defined problems requiring detailed analysis. In contrast, OODA is tailored for complex, rapidly changing environments where quick, adaptive decisions are crucial.

Case Studies

To truly appreciate the applicability and effectiveness of PDCA and OODA, it’s essential to examine real-world cases where these methodologies have been successfully employed. These examples not only provide a tangible context but also highlight the unique benefits and limitations of each framework.

A Real-World Example of PDCA in Action

Toyota Production System

Toyota, a giant in the automotive industry, employs PDCA through its Toyota Production System. The method is applied to optimize various processes, from supply chain management to quality control.

- Plan: Toyota identifies a problem area, such as a bottleneck in the assembly line, and develops a plan to eliminate it.

- Do: The plan is then implemented on a small scale, perhaps in one section of the assembly line, and data is collected for analysis.

- Check: Toyota rigorously checks whether the changes yield the desired improvements in efficiency.

- Act: If successful, the change is then rolled out across other assembly lines; otherwise, the cycle restarts.

A Real-World Example of OODA in Action

Emergency Response During Natural Disasters

The OODA loop has been used effectively in emergency management, specifically during natural disasters like hurricanes and wildfires.

- Observe: Real-time data on weather conditions, affected populations, and resource availability is collected.

- Orient: The data is then processed to understand the gravity and extent of the disaster.

- Decide: Decision-makers identify key actions, such as evacuations or resource deployment, based on the available information.

- Act: Emergency services act swiftly, often within hours, to mitigate the disaster’s impact.

Comparative Analysis

- Speed of Decision-making: The emergency response case showcases how OODA is built for rapid, real-time decisions, whereas Toyota’s application of PDCA demonstrates a slower, more meticulous approach.

- Complexity: While both cases involved complex problems, the PDCA method was employed for a well-defined issue (assembly line efficiency), whereas OODA was used for a more chaotic, rapidly evolving situation (natural disaster).

- Resource Requirements: Both methodologies require substantial resources, but PDCA usually involves a longer period of planning and data collection. OODA, although quick, requires real-time data gathering and processing capabilities.

- Adaptability: OODA’s real-world application shows a higher level of adaptability to rapidly changing situations. In contrast, PDCA, as applied by Toyota, indicates a more rigid, iterative process aimed at continuous improvement.

Depending on your specific problem and industry context, one of these frameworks may offer a more effective approach.

When to Use Which

After delving into the principles, key differences, and real-world applications of PDCA and OODA, the natural question that arises is, “When should I use which framework?” This section aims to provide clear guidelines to help you make that decision based on various scenarios and criteria.

Scenarios Where PDCA is More Appropriate

- Process Optimization: When the goal is to improve an existing process, particularly one that is well-defined and stable, PDCA offers a more structured approach.

- Quality Control: If you are aiming for incremental improvements in quality, such as reducing defect rates in manufacturing or improving customer satisfaction metrics, PDCA is highly suitable.

- Data-Driven Environments: In scenarios that require in-depth data analysis, like optimizing marketing strategies or enhancing healthcare protocols, PDCA’s methodical nature is beneficial.

- Long-Term Planning: For projects that don’t demand immediate action and allow time for planning, testing, and evaluation, PDCA is more fitting.

Scenarios Where OODA is More Fitting

- High-Stakes, Rapidly Changing Environments: In settings like emergency response or financial trading, where decisions have to be made rapidly, OODA is preferable.

- Ambiguous Situations: When you’re dealing with problems that lack clear definition and are constantly evolving, the flexibility of OODA is highly beneficial.

- Competitive Scenarios: In fast-paced markets or sports where real-time adaptability gives you an edge over competitors, OODA is more suitable.

- Resource Availability for Real-time Analysis: If your organization has the capability for real-time data collection and analysis, OODA can be very effective.

Criteria to Consider When Choosing a Framework

- Speed Requirement: Do you need immediate results, or is your timeline more flexible?

- Complexity: Is the problem well-defined, or is it volatile and ever-changing?

- Resource Availability: Do you have the resources for in-depth planning and data analysis (PDCA), or for real-time data collection and rapid action (OODA)?

- Industry Norms: What frameworks are commonly used in your industry? Each methodology has sectors where it excels.

- End Goal: Are you looking for continuous, incremental improvements (PDCA) or quick, adaptive problem-solving (OODA)?

In conclusion, both PDCA and OODA offer valuable frameworks for problem-solving and decision-making but in different contexts and scenarios. The choice between them should be made after carefully considering the specific requirements of your situation and the resources you have at your disposal.

Combining PDCA and OODA — A Synergistic Approach

While PDCA and OODA each have their unique advantages and ideal use-cases, there are scenarios where integrating the two can yield superior outcomes. This isn’t a matter of choosing one over the other but harnessing the strengths of both in a synergistic approach.

How the Two Can Complement Each Other

- Initial Planning with PDCA, Rapid Adaptation with OODA: Use PDCA for the initial planning stages to ensure that the problem is well-understood and that resources are allocated efficiently. Then, switch to OODA for real-time decision-making and adaptation.

- Data-Driven Flexibility: PDCA’s strength in data collection and analysis can feed into OODA’s orientation phase, providing a solid empirical foundation for quicker, more accurate decisions.

- Iterative Improvement: Use OODA for rapid cycles of action but periodically engage in PDCA cycles to review performance, analyze results, and set new objectives. This way, you maintain adaptability while fostering continuous improvement.

- Problem Complexity: For problems that have both well-defined and ambiguous elements, PDCA can tackle the former while OODA can be deployed for the latter.

Examples of Integrated Approaches

- Healthcare Emergency Rooms: Initial procedures and protocols can be designed using PDCA to ensure they are as effective as possible. When unpredictable emergency cases come in, medical teams could employ OODA loops to make rapid decisions based on real-time patient data.

- Supply Chain Management in FMCG: PDCA can be used to optimize the supply chain logistics and inventory levels. During sudden market changes like a spike in demand or supply interruptions, OODA can provide the adaptability needed to make quick adjustments.

- Cybersecurity: PDCA could be employed for regular security audits, vulnerability assessments, and planning system upgrades. In the event of a real-time security breach, OODA is ideal for quick identification of the threat and immediate action.

- Consulting for Business Transformation: Consultants can use PDCA to create an initial strategy for business transformation. As they start implementing changes and confront real-world challenges and feedback, OODA can guide adaptive modifications to the strategy.

By integrating PDCA and OODA, organizations can tap into both detailed, analytical planning and rapid, adaptive action. This hybrid approach offers a dynamic, responsive way to tackle complex challenges that neither method could fully address on its own.

Conclusion

In our comprehensive exploration of PDCA and OODA, two highly influential problem-solving frameworks, we’ve navigated through their origins, key steps, application across industries, and inherent strengths and weaknesses. We’ve also delved into real-world case studies to grasp their practical implications and examined various scenarios to discern when each approach is most effective. Importantly, we’ve explored how these seemingly disparate frameworks can synergistically complement each other, enriching our toolkit for tackling an array of challenges.

Final Recommendations: If you’re in an environment that values incremental improvement, relies on deep data analysis, and has the luxury of time for planning, PDCA is your go-to framework. For those in fast-paced, ever-changing scenarios requiring rapid decision-making, OODA is a better fit. However, don’t hesitate to integrate both methodologies to capture the best of structured planning and agile action. The most effective problem-solving often lies in the nuanced blend of multiple approaches.

References

- Isniah, S., Purba, H.H. and Debora, F., 2020. Plan do check action (PDCA) method: literature review and research issues. Jurnal Sistem dan Manajemen Industri, 4(1), pp.72-81.

- Johnson, C.N., 2002. The benefits fo PDCA. Quality Progress, 35(5), p.120.

- Richards, C., 2020. Boyd’s OODA loop.

- Enck, R.E., 2012. The OODA loop. Home Health Care Management & Practice, 24(3), pp.123-124.